Air pollution is a major concern worldwide, and various methods are used to control and reduce it. One such method is the use of wet scrubbers. Wet scrubbers are air pollution control devices that use water or other liquids to remove pollutants from industrial and commercial emissions. Read More…

Anguil Environmental provides highly-engineered, environmental equipment and service solutions that help clients solve complex industrial air pollution control and wastewater treatment challenges across the globe. Anguil air pollution control systems include thermal and catalytic oxidation technologies for compliance with VOC, HAP and odor regulations.

Dürr is a leading global supplier of environmental solutions and engineered products tailored to meet customers' industrial process requirements. We offer a complete portfolio of air pollution control technologies including scrubbers, wet electrostatic precipitators, thermal and catalytic oxidizers, and solvent recovery systems.

The CMM Group provides design and build, and technical engineering services for VOC emission control, odor abatement solutions and energy recovery systems. CMM Aftermarket Services team provides preventive maintenance and inspection services, controls upgrades, retrofit and rebuild services to extend the life of existing equipment. For small or large, complex projects, The CMM Group’s extensive ...

Pollution Systems designs, manufactures and installs highly reliable industrial air pollution control equipment. We offer Thermal Oxidizers, Catalytic Oxidizers, Regenerative Thermal Oxidizers, Direct Fired Oxidizers, Enclosed Flares, Gas Scrubbers, Particulate Scrubbers, Rotor Concentrators and Heat Recovery Systems. On-site services through our dedicated service company include equipment...

Meet stringent environmental regulations with Ducon's complete line of the most advanced air pollution control equipment: cyclones, scrubbers, incinerators, electrostatic precipitators, activated carbon absorbers, gas absorption towers, flue gas desulfurization, chemical strippers, NOx & VOC Control, etc.

More Wet Scrubber Manufacturers

Components of Wet Scrubbers

All wet scrubbers have the following basic components:

Inlet Ductwork

This component collects emissions from the source and transports them to the scrubber.

Scrubber Vessel

This is the main component of the wet scrubber, where the scrubbing liquid is introduced and the pollutants are removed.

Spray Nozzles

These are used to spray the scrubbing liquid into the scrubber vessel.

Packing Material

This component increases the surface area available for the pollutants to interact with the scrubbing liquid.

Mist Eliminator

This component removes any excess water vapor or mist from the scrubber vessel before the gas is discharged to the atmosphere.

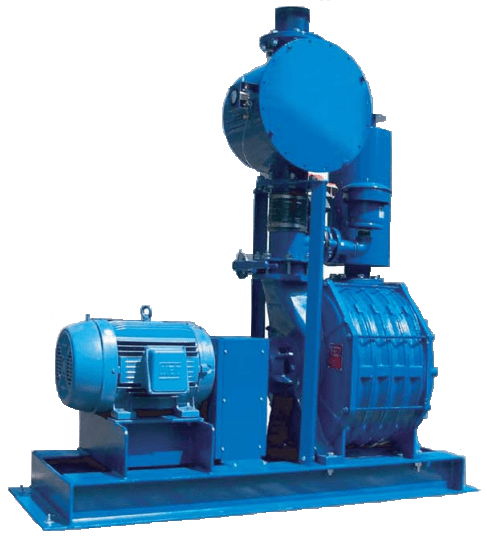

Variations of Wet Scrubbers

There are various types of wet scrubbers, each with specific design differences and applications. Some of the most common variations include:

Venturi Scrubbers

These scrubber use a narrow throat to increase the velocity of the emissions and create a pressure drop, which enhances the interaction between the emissions and the scrubbing liquid.

Spray Tower Scrubbers

These scrubbers use a series of spray nozzles to introduce the scrubbing liquid into the vessel, which is then collected at the bottom and recycled.

Packed Bed Scrubbers

These scrubbers use a bed of packing material to increase the surface area available for the pollutants to interact with the scrubbing liquid.

Considerations Regarding Wet Scrubbers

Wet scrubbers do have some considerations, including:

High Energy Consumption

The use of water and other liquids requires significant energy to pump and distribute.

High Maintenance Costs

Wet scrubbers require frequent maintenance to prevent clogging, corrosion, and other issues.

Water Treatment

The scrubbing liquid must be treated and disposed of properly to prevent contamination of water sources.

Benefits of Wet Scrubbers

Despite these considerations, wet scrubbers offer several benefits for air pollution control, including:

Cost-Effectiveness

Wet scrubbers are a cost-effective solution for air pollution control compared to other methods.

Reliability

Wet scrubbers are a reliable method for air pollution control, and they can operate continuously without interruption.

Versatility

Wet scrubbers can be used to control a wide range of pollutants and emissions, making them suitable for various industries.

Applications of Wet Scrubbers

Due to their benefits, wet scrubbers are used in various industries, including:

Chemical and Petrochemical Manufacturing

In this industry, wet scrubbers are commonly used to control emissions of acidic gasses such as hydrochloric acid, sulfuric acid, and hydrogen fluoride. These emissions are produced during the production of various chemicals and can cause severe environmental and health problems. Wet scrubbers are used to neutralize these acidic gasses, reducing their harmful effects.

Metal Processing

Wet scrubbers are commonly used in metal processing plants to control emissions of particulate matter, fumes, and other pollutants. These emissions are produced during various metal processing operations, such as welding, smelting, and casting. Wet scrubbers are used to capture and remove these pollutants before they can be released into the environment.

Pharmaceutical Manufacturing

Wet scrubbers are used in the pharmaceutical industry to control emissions of volatile organic compounds (VOCs) and other pollutants. These emissions are produced during the manufacturing process of various pharmaceutical products and can cause environmental and health problems. Wet scrubbers are used to capture and remove these pollutants, ensuring that the air quality in and around the manufacturing facility is safe.

Food Processing

Wet scrubbers are commonly used in the food processing industry to control emissions of particulate matter and other pollutants. These emissions are produced during various food processing operations, such as baking, frying, and cooking. Wet scrubbers are used to capture and remove these pollutants, ensuring that the air quality in and around the processing facility is safe.

Power Generation

Wet scrubbers are commonly used in power plants to control emissions of sulfur dioxide and other pollutants. These emissions are produced during the burning of fossil fuels, such as coal and oil, and can cause severe environmental and health problems. Wet scrubbers are used to capture and remove these pollutants, reducing their harmful effects.

Waste Incineration

Wet scrubbers are commonly used in waste incineration facilities to control emissions of acidic gasses, particulate matter, and other pollutants. These emissions are produced during the incineration of various types of waste, such as municipal solid waste, medical waste, and hazardous waste. Wet scrubbers are used to capture and remove these pollutants, ensuring that the air quality in and around the incineration facility is safe.

Cement Manufacturing

Wet scrubbers are used in cement manufacturing plants to control emissions of particulate matter and other pollutants.

Semiconductor Manufacturing

Wet scrubbers are used in semiconductor manufacturing facilities to control emissions of various chemicals and other pollutants.

Textile Manufacturing

Wet scrubbers are used in textile manufacturing plants to control emissions of particulate matter and other pollutants.

Mining

Wet scrubbers are used in mining operations to control emissions of particulate matter and other pollutants produced during drilling and other mining operations.

Choosing the Right Wet Scrubber Manufacturer

To ensure you have the most positive outcome when purchasing a wet scrubber from a wet scrubber manufacturer, it is important to compare several companies using our directory of wet scrubber manufacturers. Each wet scrubber manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or to request a quote. Review each wet scrubber business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple wet scrubber companies with the same form.

Air Compressors

Air Compressors  Air Filters

Air Filters Air Pollution Control

Air Pollution Control Blowers

Blowers Dust Collectors

Dust Collectors Industrial Vacuum Cleaning Equipment

Industrial Vacuum Cleaning Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services