Air pollution control equipment is equipment that removes Volatile Organic Compounds (VOCs) and Hazardous Air Pollutants (HAPs) from the air, like sulfuric gases, fumes, odors and vapors. VOCs and HAPs pose a threat to the environment, local ecosystems and human health. They result, for example, in acid rain, smog, carbon emissions and overall climate change. Read More...

Anguil Environmental provides highly-engineered, environmental equipment and service solutions that help clients solve complex industrial air pollution control and wastewater treatment challenges across the globe. Anguil air pollution control systems include thermal and catalytic oxidation technologies for compliance with VOC, HAP and odor regulations.

Dürr is a leading global supplier of environmental solutions and engineered products tailored to meet customers' industrial process requirements. We offer a complete portfolio of air pollution control technologies including scrubbers, wet electrostatic precipitators, thermal and catalytic oxidizers, and solvent recovery systems.

The CMM Group provides design and build, and technical engineering services for VOC emission control, odor abatement solutions and energy recovery systems. CMM Aftermarket Services team provides preventive maintenance and inspection services, controls upgrades, retrofit and rebuild services to extend the life of existing equipment. For small or large, complex projects, The CMM Group’s extensive ...

Pollution Systems designs, manufactures and installs highly reliable industrial air pollution control equipment. We offer Thermal Oxidizers, Catalytic Oxidizers, Regenerative Thermal Oxidizers, Direct Fired Oxidizers, Enclosed Flares, Gas Scrubbers, Particulate Scrubbers, Rotor Concentrators and Heat Recovery Systems. On-site services through our dedicated service company include equipment...

Meet stringent environmental regulations with Ducon's complete line of the most advanced air pollution control equipment: cyclones, scrubbers, incinerators, electrostatic precipitators, activated carbon absorbers, gas absorption towers, flue gas desulfurization, chemical strippers, NOx & VOC Control, etc.

More Air Pollution Control Equipment Manufacturers

Air Pollution Control Equipment

There are various forms of air pollution control equipment, each with their unique method of combating air pollution, benefits, and limitations. We explore many types of air pollution control equipment below in greater detail.

Scrubbers

Scrubbers are air pollution control devices designed to remove pollutants from industrial exhaust gases. They function by introducing a liquid or gas (often water or a chemical solution) into the exhaust stream, which comes into contact with the pollutants. Through various mechanisms such as absorption, adsorption, or chemical reactions, scrubbers neutralize or capture the pollutants before they are released into the atmosphere. Scrubbers

are particularly effective in targeting pollutants like sulfur dioxide (SO2), nitrogen oxides (NOx), and particulate matter (PM), which are common emissions in industries such as power plants, refineries, and steel mills.

However, scrubbers do have certain limitations. One limitation is their high energy consumption. The process of introducing and dispersing the liquid or gas into the exhaust stream requires significant energy input. Additionally, the liquid used in scrubbers can create a waste stream that requires proper treatment and disposal. This liquid waste, often containing captured pollutants, needs to be managed to prevent any environmental impact. Moreover, scrubbers may have limitations in effectively capturing certain pollutants, such as fine particulate matter or volatile organic compounds (VOCs), which may require additional control technologies or modifications to the scrubber design.

To address these limitations, manufacturers of scrubbers are continuously working on advancements in technology. They are developing more energy-efficient scrubber systems that minimize the energy requirements for the liquid dispersion process. Additionally, efforts are being made to optimize the design of scrubbers to enhance pollutant capture efficiency, especially for challenging pollutants like fine particulate matter and VOCs. Moreover, advancements in waste management systems are being implemented to improve the treatment and disposal of the captured pollutants, reducing the environmental impact associated with the liquid waste generated by scrubbers. These continuous improvements aim to make scrubbers more effective, efficient, and environmentally friendly in combating air pollution.

Dust Collectors

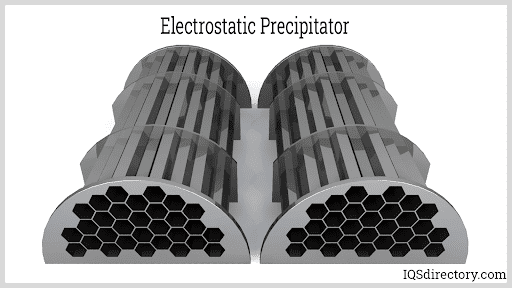

Dust collectors are air pollution control devices specifically designed to capture and remove airborne particles from industrial processes. They operate by drawing contaminated air through a filtration system, where dust and particulate matter are trapped and separated from the air stream. The filtration media used in dust collectors can vary, ranging from fabric bags to filter cartridges or electrostatic precipitators. Dust collectors effectively combat particulate pollution, including fine dust and hazardous particles, in industries such as mining, woodworking, and pharmaceutical manufacturing.

However, dust collectors also have their limitations. One limitation is their ability to handle high-temperature gases. Excessive heat can damage or degrade the filtration media, reducing its effectiveness and lifespan. Another challenge is encountered with certain types of fine particles that can bypass the filtration media, resulting in incomplete removal of pollutants. Additionally, dust collectors may require periodic maintenance, including cleaning or replacing the filter media, to ensure optimal performance. This maintenance can lead to operational downtime and associated costs.

To overcome these limitations, manufacturers of dust collectors are continuously working on developing innovative filtration media that can withstand higher temperatures without compromising performance. These media may include materials with enhanced heat resistance or specialized coatings. Moreover, advancements in monitoring systems and control mechanisms are helping to optimize dust collector operation, enabling timely maintenance and filter media replacement based on actual conditions. These advancements aim to improve the efficiency, reliability, and longevity of dust collectors, enhancing their ability to combat air pollution effectively.

Oxidizers

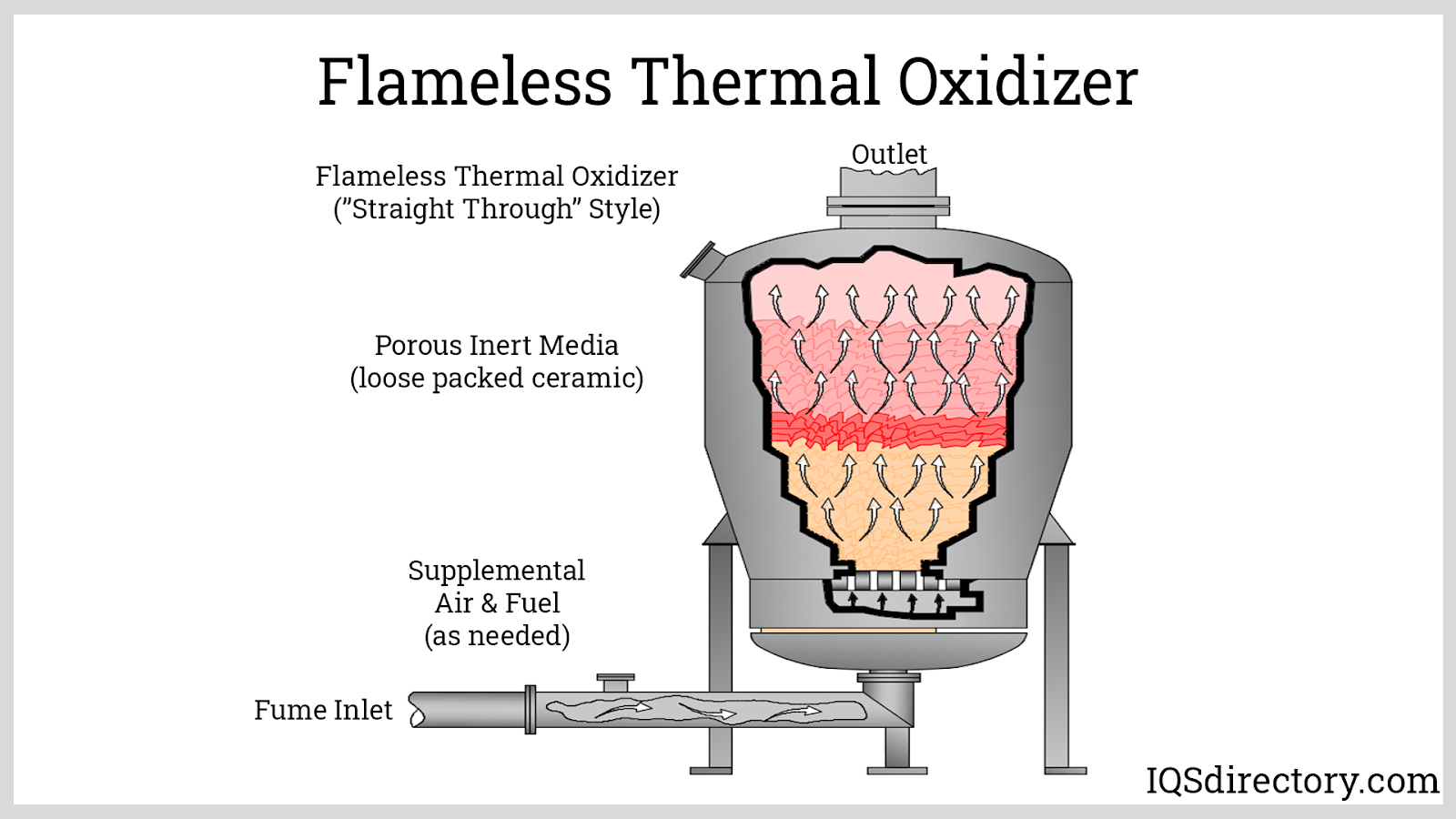

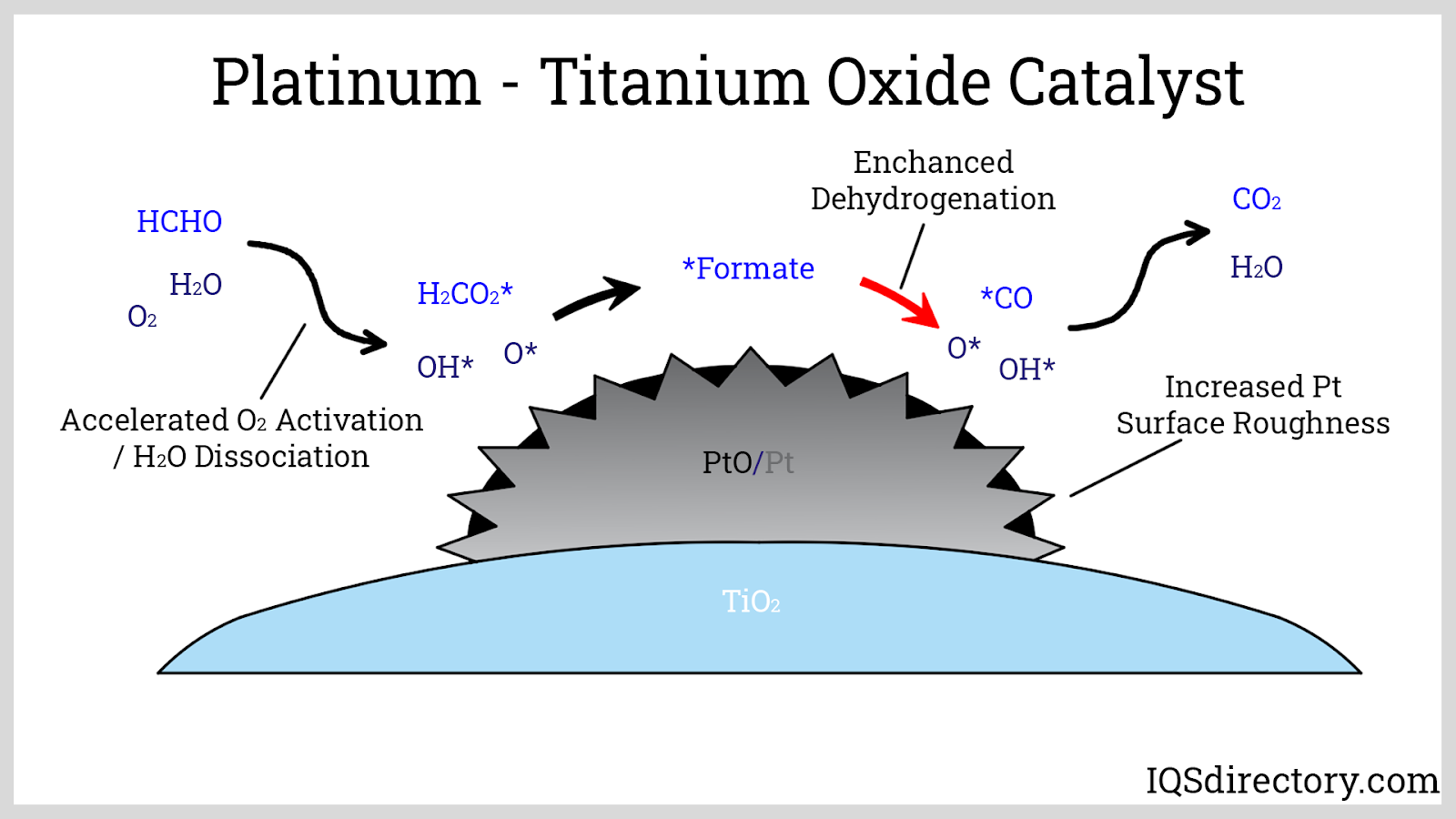

Oxidizers are air pollution control devices used to eliminate volatile organic compounds (VOCs) and hazardous air pollutants (HAPs) from industrial exhaust gases. They operate by subjecting the pollutants to high temperatures in the presence of oxygen, initiating a chemical reaction that oxidizes the compounds and converts them into less harmful byproducts. Oxidizers utilize various combustion technologies, such as thermal oxidizers, catalytic oxidizers, or regenerative oxidizers, depending on the specific application and pollutant composition. Industries such as chemical manufacturing, printing, and painting utilize oxidizers to control VOC emissions.

Again, oxidizers also have their limitations. One limitation is their high energy consumption. Achieving the necessary temperatures for effective oxidation requires substantial energy input, resulting in increased operational costs. Additionally, some oxidation processes can generate secondary pollutants, such as nitrogen oxides (NOx) or carbon monoxide (CO), depending on the combustion conditions and the composition of the exhaust gases. This necessitates careful design and optimization to minimize the formation of these secondary pollutants.

To overcome these limitations, manufacturers of oxidizers are actively working on developing more efficient combustion systems and heat recovery techniques to reduce energy consumption. Catalytic oxidizers, for example, offer lower operating temperatures and reduced energy requirements compared to thermal oxidizers. Additionally, advancements in catalyst materials and design aim to enhance pollutant removal efficiency while minimizing the formation of secondary pollutants. Furthermore, the integration of control systems and monitoring technologies allows for better process optimization, ensuring optimal performance and minimizing energy waste. These ongoing improvements contribute to making oxidizers more effective, energy-efficient, and environmentally friendly in the fight against air pollution.

Mist Collectors

Mist collectors, also known as oil mist eliminators, are air pollution control devices designed to capture and remove liquid droplets or mists from industrial exhaust streams. They operate by utilizing various mechanisms such as impaction, interception, and coalescence to separate the mist particles from the air. Mist collectors are effective in combating pollutants such as oil mists, coolant mists, and fumes generated by processes like metalworking, machining, and industrial cooling systems. These collectors typically consist of filters or coalescing media that enable the mist particles to coalesce into larger droplets, which can then be drained or collected for proper disposal.

Like all air pollution control equipment, sadly, mist collectors also have limitations. One limitation is their effectiveness in handling high-viscosity mists. Mists with high viscosity or sticky nature can be challenging to capture and may require specialized collector designs or additional pre-treatment steps. Furthermore, mist collectors require periodic maintenance to prevent pressure drop and filter clogging. Regular maintenance, including cleaning or replacing the filters, is necessary to ensure optimal performance. As a result, failure to adequately maintain mist collectors can result in reduced efficiency and potential release of mist particles back into the air stream.

To address these limitations, manufacturers of mist collectors are developing enhanced filtration media that can efficiently capture and coalesce high-viscosity mists. These media may have specialized surface treatments or modifications to improve mist droplet capture efficiency. Additionally, advancements in mist collector design aim to minimize pressure drop and streamline maintenance processes. Some collectors already incorporate automatic cleaning mechanisms or indicators that help operators monitor the condition of the filters and schedule maintenance accordingly. These advancements contribute to the overall effectiveness and longevity of mist collectors, ensuring efficient mist particle removal and reducing the associated maintenance challenges.

Benefits of Air Pollution Control Equipment

Air pollution control equipment provides numerous benefits for individuals, businesses, and the world as a whole. For individuals, the use of such equipment helps safeguard their health by reducing exposure to harmful pollutants present in the air. By capturing and removing pollutants, air pollution control equipment contributes to cleaner and healthier air, which can prevent respiratory illnesses, allergies, and other adverse health effects. Additionally, cleaner air improves overall quality of life, allowing individuals to enjoy outdoor activities without the risk of breathing in pollutants.

For businesses, air pollution control equipment plays a crucial role in meeting regulatory requirements and ensuring compliance with environmental standards. It helps businesses reduce their environmental impact by minimizing emissions of pollutants, thus avoiding fines and penalties. Implementing effective pollution control measures can also enhance a company’s reputation and demonstrate its commitment to sustainable practices, which can be attractive to environmentally conscious customers, investors, and stakeholders. Furthermore, by reducing pollution, businesses can create a healthier and more productive work environment for their employees, leading to increased productivity and employee satisfaction.

On a global scale, air pollution control equipment contributes to the preservation and protection of the environment. It helps combat climate change by reducing the release of greenhouse gases and other pollutants that contribute to global warming. By mitigating air pollution, these technologies contribute to the conservation of natural resources and ecosystems, promoting biodiversity and ecological balance. Moreover, they support sustainable development practices by fostering cleaner and more sustainable industrial processes, promoting energy efficiency, and reducing waste generation. Ultimately, the use of air pollution control equipment contributes to a cleaner, safer, and more sustainable world for current and future generations.

Applications of Air Pollution Control Equipment

Air pollution control equipment finds diverse applications across various industries and sectors. In industrial manufacturing, for example, these systems are crucial for controlling emissions generated by processes such as metalworking, chemical production, cement manufacturing, and food processing. Power generation facilities, meanwhile, utilize pollution control equipment to mitigate the release of pollutants from the combustion of fossil fuels, including coal-fired power plants, natural gas turbines, and biomass energy systems. The automotive industry also heavily relies on emission control systems to reduce harmful gases from vehicle exhaust, including catalytic converters and particulate filters. Additionally, air pollution control equipment is utilized in commercial and residential spaces to improve indoor air quality, such as HVAC systems with air filters and ventilation systems designed to remove contaminants and maintain healthy indoor environments. These applications demonstrate the wide-ranging use of air pollution control equipment in various sectors, all aimed at reducing pollution and improving air quality.

Selecting Appropriate Air Pollution Control Equipment

Selecting appropriate air pollution control equipment for a specific application requires careful consideration of several factors. To begin with, understanding the specific requirements of the industry or application is crucial. This includes identifying the types and concentrations of pollutants that need to be controlled. Assessing the pollutant composition helps determine the most suitable control technology, whether it’s scrubbers, dust collectors, oxidizers, or mist collectors. Environmental and regulatory factors should also be taken into account to ensure compliance with emission standards and local regulations.

Additionally, considering the operational conditions and constraints of the application is essential. Factors such as temperature, pressure, airflow rates, and particulate characteristics should be evaluated to ensure that the chosen equipment can handle the specific conditions effectively. Other practical considerations include available space, maintenance requirements, and energy consumption.

To make an informed decision, it is recommended to consult with experts and manufacturers of air pollution control equipment. They can provide valuable insights and expertise based on their experience and knowledge of the industry. Engaging in a thorough assessment and feasibility study with their guidance can help identify the most suitable equipment for the specific application, taking into account performance requirements, cost-effectiveness, and environmental impact.

Overall, selecting appropriate air pollution control equipment involves a comprehensive evaluation of the specific needs, pollutant characteristics, regulatory requirements, and operational conditions to ensure the chosen equipment is well-suited to effectively control and mitigate air pollution in the given application.

The Future of Air Pollution Control Equipment

The potential future of air pollution control equipment holds exciting possibilities for advancements in technology and approaches. Integration of Internet of Things (IoT) and smart technology is expected to play a significant role. This integration would allow for real-time monitoring, data collection, and analysis of air pollution control systems, enabling proactive maintenance, optimization, and performance monitoring. Additionally, advancements in filtration and purification methods are being explored. This includes the development of advanced filter media, such as nanofiber-based filters, that offer higher efficiency and better pollutant capture capabilities. Furthermore, there is a growing emphasis on renewable energy-powered systems for air pollution control. Integration of renewable energy sources, such as solar and wind power, can help reduce the carbon footprint of these systems. Collaborative efforts among researchers, manufacturers, and policymakers worldwide are also contributing to the future of air pollution control equipment. This collaboration aims to foster knowledge sharing, innovation, and the development of more effective and sustainable solutions. Ultimately, the future of air pollution control equipment is anticipated to bring about enhanced performance, improved energy efficiency, and smarter, greener technologies for combating air pollution and protecting our environment.

Choosing the Right Air Pollution Control Equipment Supplier

To ensure you have the most beneficial outcome when purchasing air pollution control equipment from an air pollution control equipment supplier, it is beneficial to compare several businesses using our directory of air pollution control equipment suppliers. There, each air pollution control equipment supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or to request a quote. Review each air pollution control equipment business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple air pollution control equipment companies with the same form.

Check out our Dust Collector website

Check out our Parts Washers website

Air Compressors

Air Compressors  Air Filters

Air Filters Air Pollution Control

Air Pollution Control Blowers

Blowers Dust Collectors

Dust Collectors Industrial Vacuum Cleaning Equipment

Industrial Vacuum Cleaning Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services