Air filtration systems are set up to block air pollution, which can be invisible to the eye. Air pollution in industrial environments is not uncommon and ranges from dust and pollen particles to microbes, gasses, and chemicals. Read More…

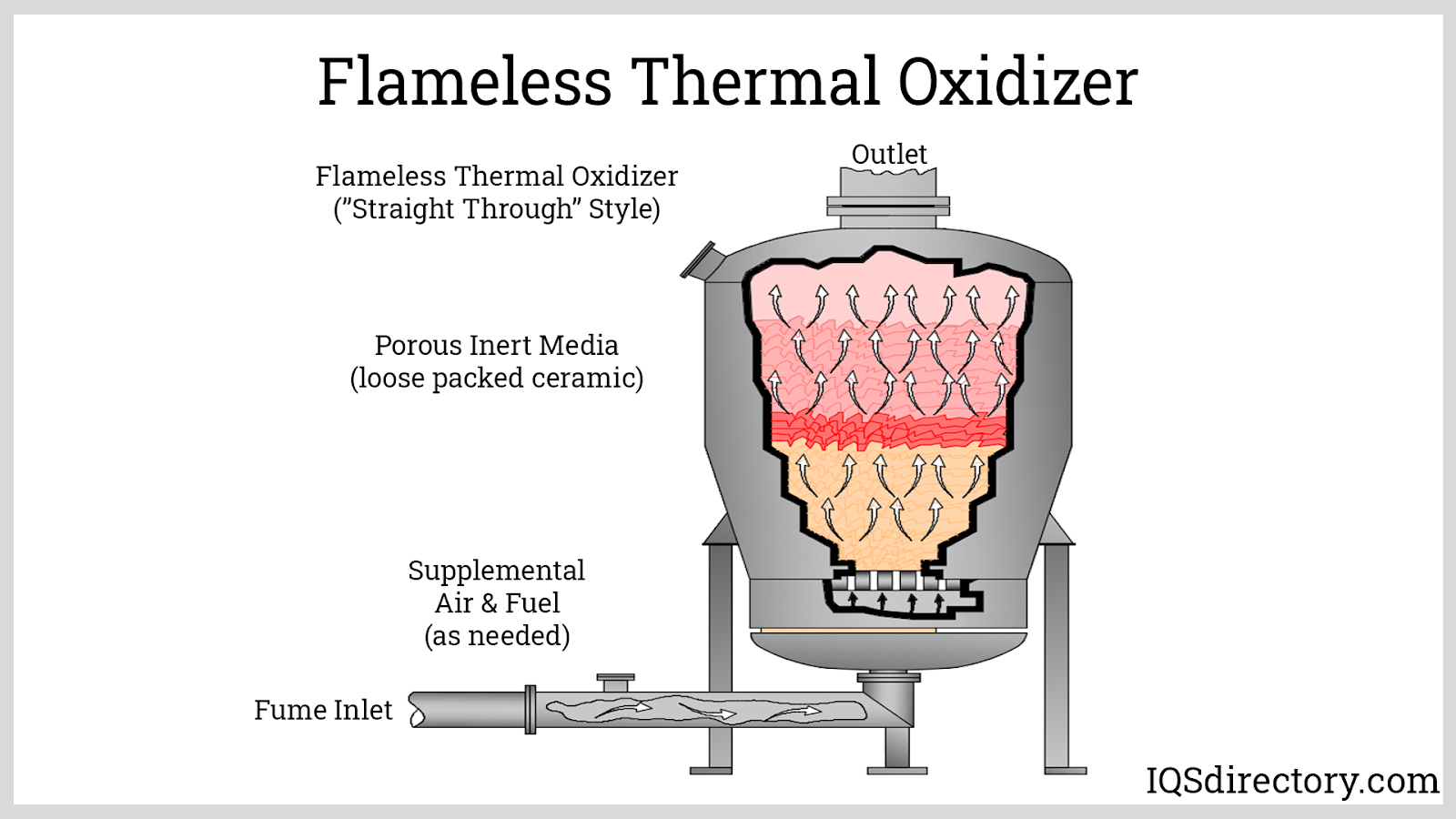

Anguil Environmental provides highly-engineered, environmental equipment and service solutions that help clients solve complex industrial air pollution control and wastewater treatment challenges across the globe. Anguil air pollution control systems include thermal and catalytic oxidation technologies for compliance with VOC, HAP and odor regulations.

Dürr is a leading global supplier of environmental solutions and engineered products tailored to meet customers' industrial process requirements. We offer a complete portfolio of air pollution control technologies including scrubbers, wet electrostatic precipitators, thermal and catalytic oxidizers, and solvent recovery systems.

The CMM Group provides design and build, and technical engineering services for VOC emission control, odor abatement solutions and energy recovery systems. CMM Aftermarket Services team provides preventive maintenance and inspection services, controls upgrades, retrofit and rebuild services to extend the life of existing equipment. For small or large, complex projects, The CMM Group’s extensive ...

Pollution Systems designs, manufactures and installs highly reliable industrial air pollution control equipment. We offer Thermal Oxidizers, Catalytic Oxidizers, Regenerative Thermal Oxidizers, Direct Fired Oxidizers, Enclosed Flares, Gas Scrubbers, Particulate Scrubbers, Rotor Concentrators and Heat Recovery Systems. On-site services through our dedicated service company include equipment...

Meet stringent environmental regulations with Ducon's complete line of the most advanced air pollution control equipment: cyclones, scrubbers, incinerators, electrostatic precipitators, activated carbon absorbers, gas absorption towers, flue gas desulfurization, chemical strippers, NOx & VOC Control, etc.

More Air Filtration System Manufacturers

Alternatives to traditional air filtration systems include ion diffusers, which neutralize air and ozone air filtration, which destroy rather than trap particles. Available in many types and configurations, air filtration systems are available in standard and custom configurations for easy installment and optimal efficiency.

Air filtration systems are set up to block air pollution, which can be invisible to the eye. Air pollution in industrial environments is not uncommon and ranges from dust and pollen particles to microbes, gasses, and chemicals. Although widespread, air pollutants can trigger serious allergic reactions in humans and animals as well as promote the spread of airborne disease and clog electronic or mechanical apparatus causing reduced productivity or even equipment failure in extreme cases.

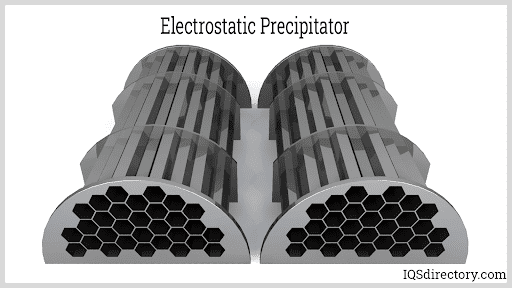

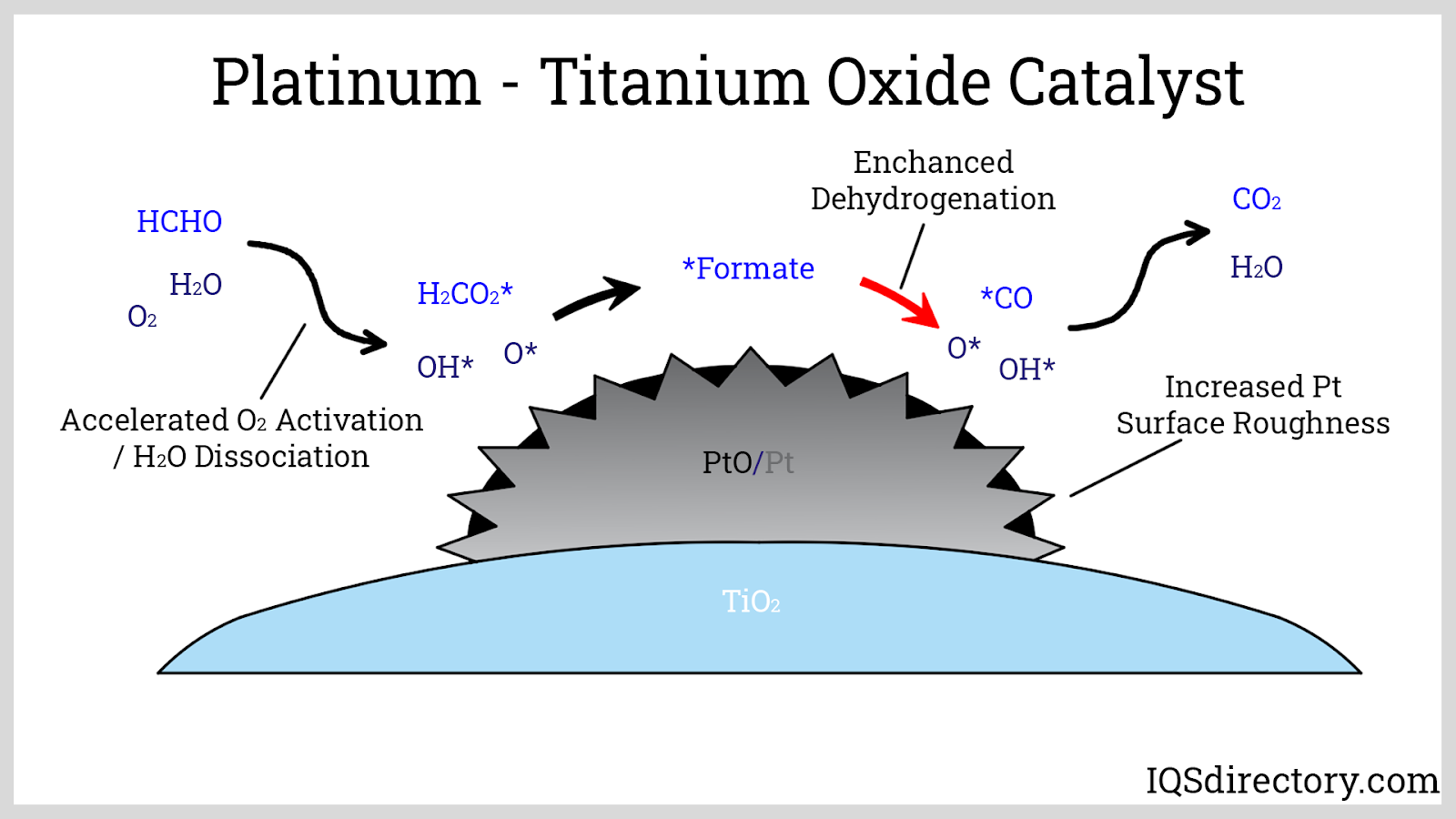

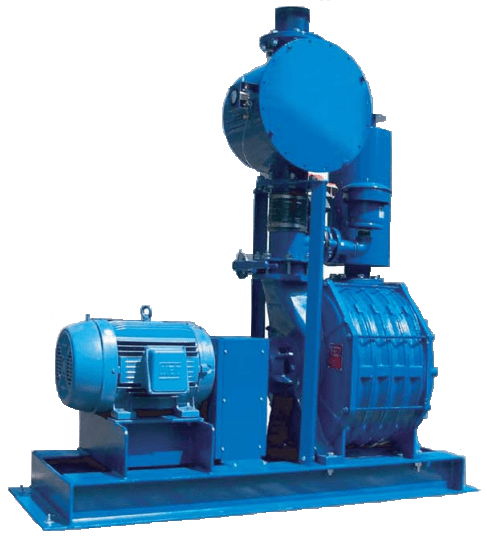

Electronic, clean room, laboratory, medical, pharmaceutical, and food and chemical processing industries utilize precision air pollution control such as high-efficiency particulate air (HEPA) and ultra low particulate air filters (ULPA) which remove particles as small as 0.3 nanometers. While manufacturing, automotive, aerospace and other industrious applications may utilize these same filters, large particle removal will often suffice and prevent equipment clogging while promoting a healthy and safe work environment for both workers and machinery. Not only an industrial form of filtration, air filters are often installed in commercial and residential ventilation systems as well.In general, most air filter systems use an electronic blower to push or pull air through a filter, or several. The impurities and contaminants, such as dust, pollen, mold, bacteria, metallic powder, gases and chemicals can be collected for proper disposal or recycling as needed while the air is returned to circulation or exhausted into the atmosphere. Specific types of air filters include bag filters, box filters, fan filters, panel and cartridge filters. Each type uses some sort of filter media. As air or gas passes through the filter, a mat or barrier, the impurities become trapped, or in some cases dissolved per chemical reactions. Common materials employed in the construction of the aforementioned filters include acrylic, activated carbon, aluminum wire, electrostatic fabric, fiberglass, paper, polyurethane foam, polyester, cotton and non-woven materials. The choice of material should take into account the intended use of a filtration system. Common considerations include porosity, efficiency, flow rate, filter length, pressure drop and ply. Each filter may be used alone or in conjunction with others for optimal air purification. While some filters are reusable through repeated washing, others are designed for limited use followed by replacement. Alternatives to traditional air filtration systems include ion diffusers, which neutralize air and ozone air filtration, which destroy rather than trap particles. Available in many types and configurations, air filtration systems are available in standard and custom configurations for easy installment and optimal efficiency.

Air Compressors

Air Compressors  Air Filters

Air Filters Air Pollution Control

Air Pollution Control Blowers

Blowers Dust Collectors

Dust Collectors Industrial Vacuum Cleaning Equipment

Industrial Vacuum Cleaning Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services