Solids or liquids that easily release oxygen or even other oxidizing gases (such as chlorine, bromine, or fluorine) are known as oxidizing materials. They also consist of substances that chemically oxidize combustible (burnable) substances, in which oxygen reacts chemically with another substance, raising the possibility of fire or explosion. This reaction can happen spontaneously at ambient temperature or when lightly heated. Strong fire and explosion risks can arise from oxidizing liquids and solids. By burning or oxidizing flammable materials or fluids in the exhaust air stream, oxidizers are pollution control devices that process exhaust air streams. They then discharge the harmful-free gases into the environment. Read More…

Anguil Environmental provides highly-engineered, environmental equipment and service solutions that help clients solve complex industrial air pollution control and wastewater treatment challenges across the globe. Anguil air pollution control systems include thermal and catalytic oxidation technologies for compliance with VOC, HAP and odor regulations.

Dürr is a leading global supplier of environmental solutions and engineered products tailored to meet customers' industrial process requirements. We offer a complete portfolio of air pollution control technologies including scrubbers, wet electrostatic precipitators, thermal and catalytic oxidizers, and solvent recovery systems.

The CMM Group provides design and build, and technical engineering services for VOC emission control, odor abatement solutions and energy recovery systems. CMM Aftermarket Services team provides preventive maintenance and inspection services, controls upgrades, retrofit and rebuild services to extend the life of existing equipment. For small or large, complex projects, The CMM Group’s extensive ...

Pollution Systems designs, manufactures and installs highly reliable industrial air pollution control equipment. We offer Thermal Oxidizers, Catalytic Oxidizers, Regenerative Thermal Oxidizers, Direct Fired Oxidizers, Enclosed Flares, Gas Scrubbers, Particulate Scrubbers, Rotor Concentrators and Heat Recovery Systems. On-site services through our dedicated service company include equipment...

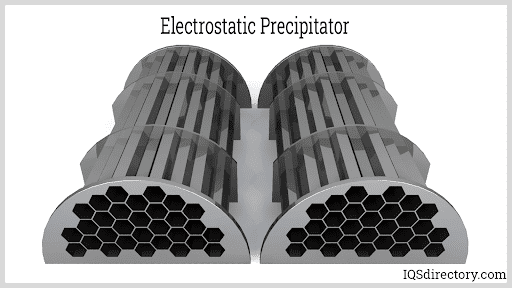

Meet stringent environmental regulations with Ducon's complete line of the most advanced air pollution control equipment: cyclones, scrubbers, incinerators, electrostatic precipitators, activated carbon absorbers, gas absorption towers, flue gas desulfurization, chemical strippers, NOx & VOC Control, etc.

More Oxidizer Manufacturers

The idea is straightforward: all of the hazardous particles are burned rather than just some of them. They are used to efficiently remove particulate matter (PM), volatile organic contaminants (VOC), and toxic air pollutants (TAP). While oxidizers may not necessarily remove all pollutants and particulates from an air stream, the reaction's byproducts are non-toxic and easier to control than the original pollutants.

Operation of Oxidizers

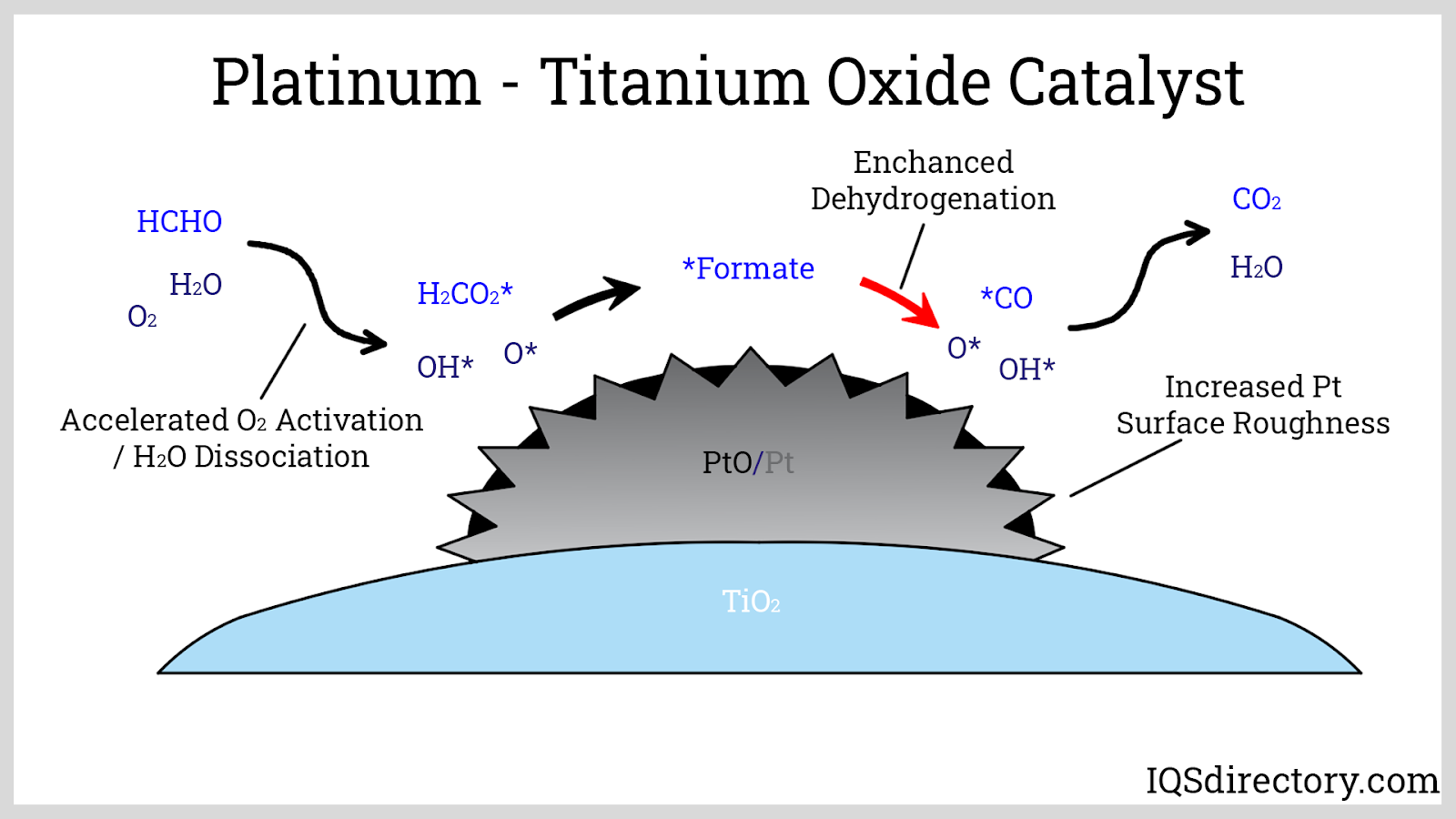

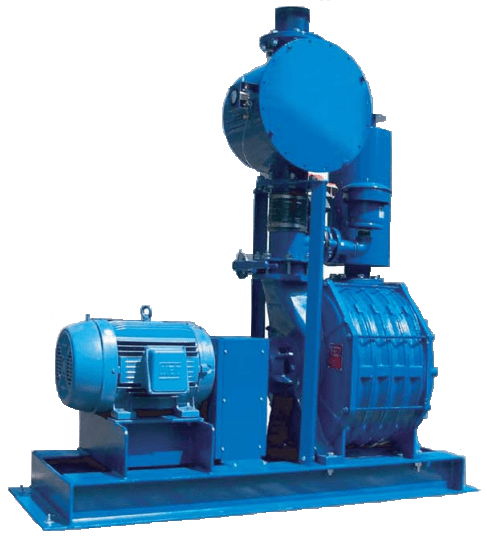

Although extremely specialized, oxidizers' fundamental operation is relatively easy. Forced industrial processing-contaminated air is introduced into an oxidizer's primary chamber. The materials are processed to the point of combustion or a chemical reaction, which burns the toxic solids or liquids and transforms them into less harmful byproducts that can be screened or gathered for disposal. Thermal and catalytic oxidizers are the two primary categories. Thermal oxidizers can be regenerative or recuperative regarding heat transport and storage. Since thermal oxidizers employ extremely high heat to cause the combustion of impurities, this is crucial for reducing operational costs. Catalytic converters also break down hazardous chemicals at a significantly lower temperature. A metal catalyst, like platinum or palladium, is employed to encourage oxidation inside the combustion chamber to achieve this. The usage of rotor concentrator-based oxidizers is becoming more widespread. These oxidizers treat air flows through a continually revolving wheel saturated with adsorbent materials. The operating area, capacity, and type of pollutants in a product stream all play a significant role in the oxidizer used. Care should be used in selection to provide the most feasible destruction effectiveness, reducing atmospheric pollution.

Types of Oxidizers

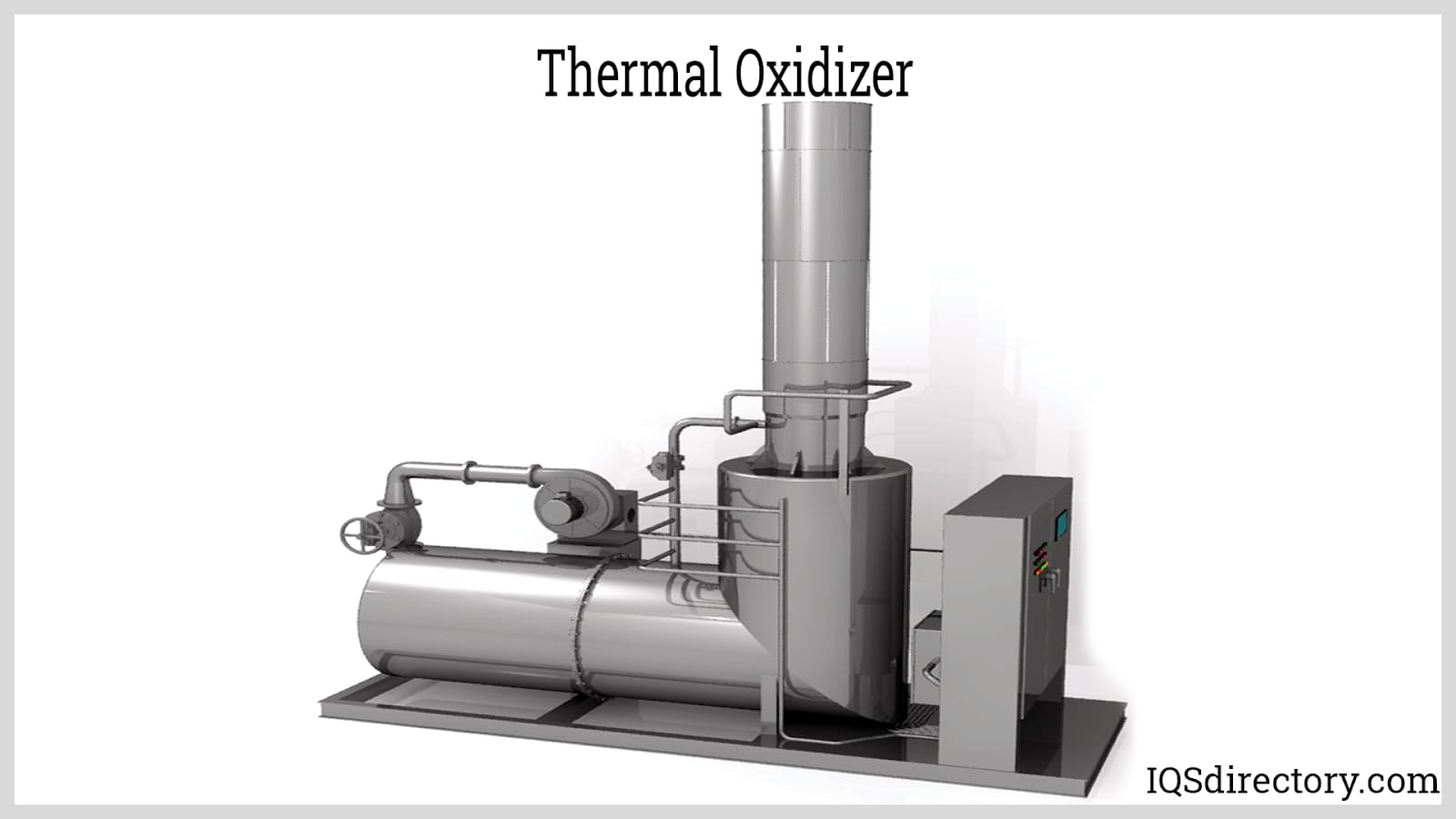

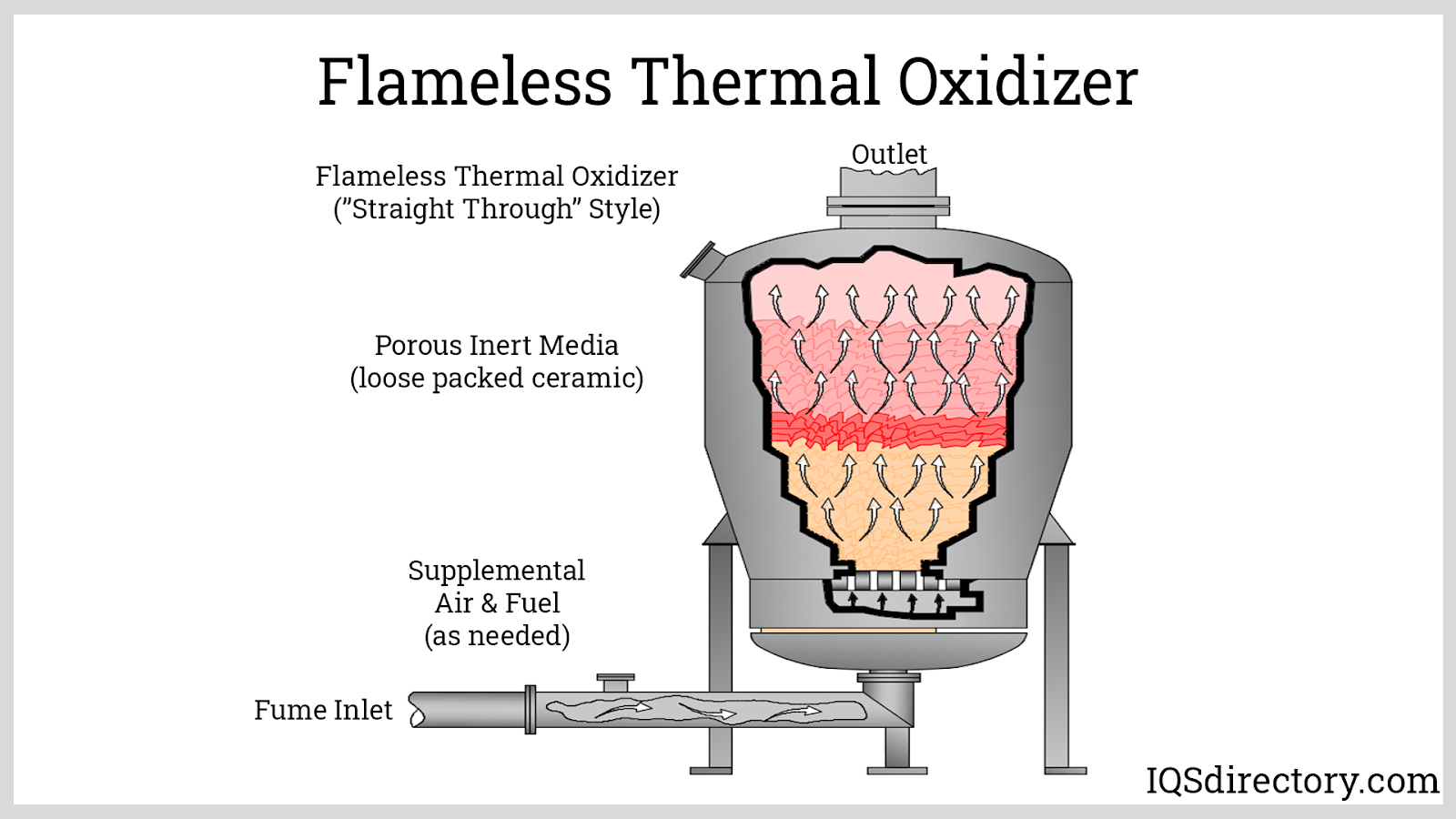

Thermal Oxidizers

The stream's flammable organic or inorganic contaminants should be incinerated using fire plumes. Hazardous gas breakdown takes place between 800°F and 2000°F at extremely high temperatures. Afterburner, also called the direct-fired thermal oxidizer, regenerative thermal oxidizers, and recuperative oxidizers are subcategories of thermal oxidizers.

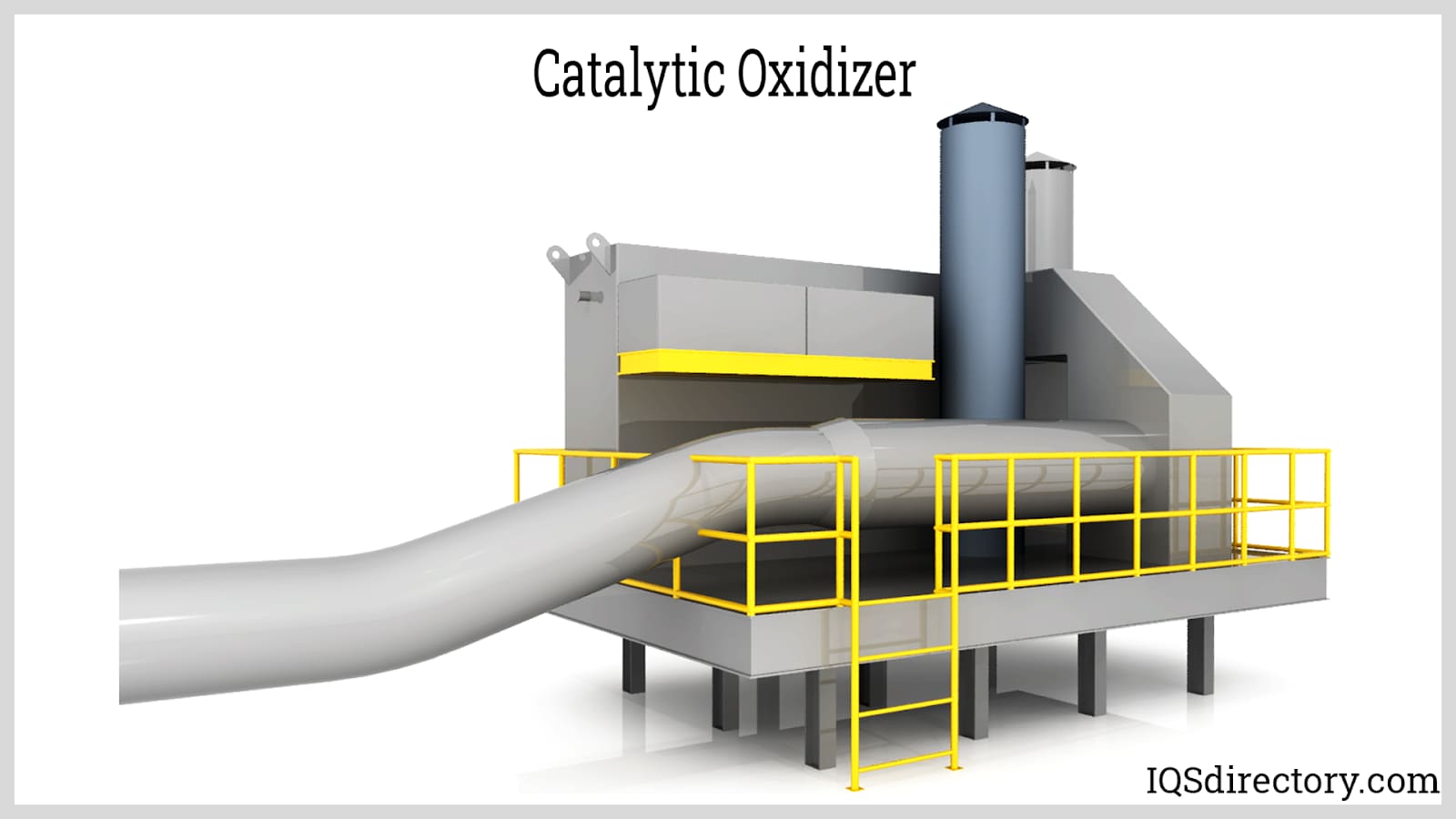

Catalytic Oxidizers

Catalytic oxidizers, also known as catalytic incinerators, function similarly to thermal oxidizers but use catalysts to speed up the oxidation reaction or burning of pollutants. The pollutants can be destroyed at much lower temperatures, between 644 °F and 1,004 °F, when a catalyst is present to speed up the combustion rate. Precious metal catalysts, usually in the shape of a bed of platinum or rhodium, are used to speed up oxidizing reactions.

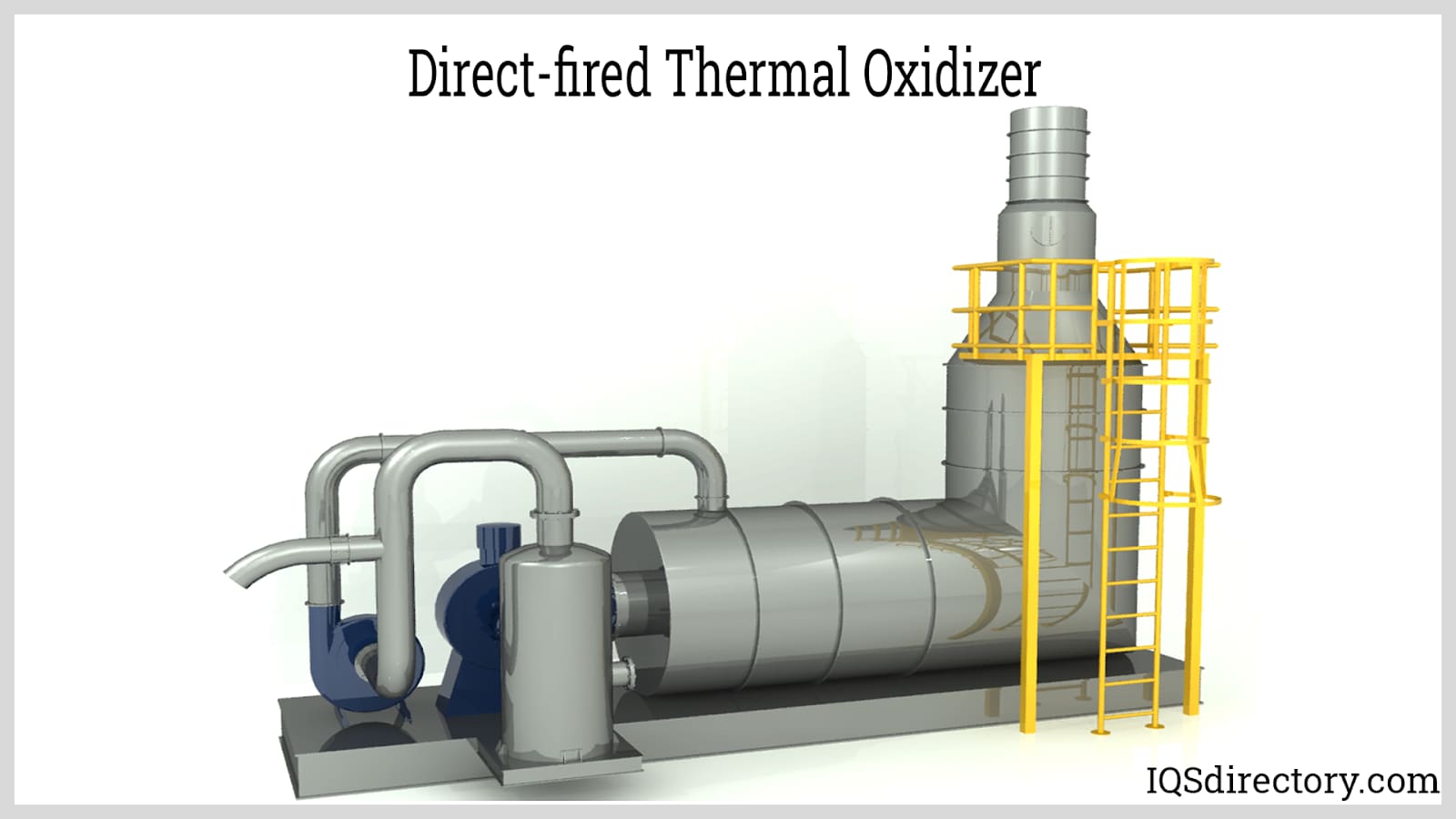

Direct-Fired Thermal Oxidizers

The simplest thermal oxidizer, an afterburner, exposes a firebox to dangerous gases intermingled in the stream. The gases must stay in the combustor for a specific time, or "residence time," to burn the biological compounds efficiently. Therefore, afterburners operate at extremely elevated temperatures, from 1,800 °F to around 2,190 °F, with airflow rates ranging between 0.24 and 24 cubic meters every second to achieve maximum removal efficiency.

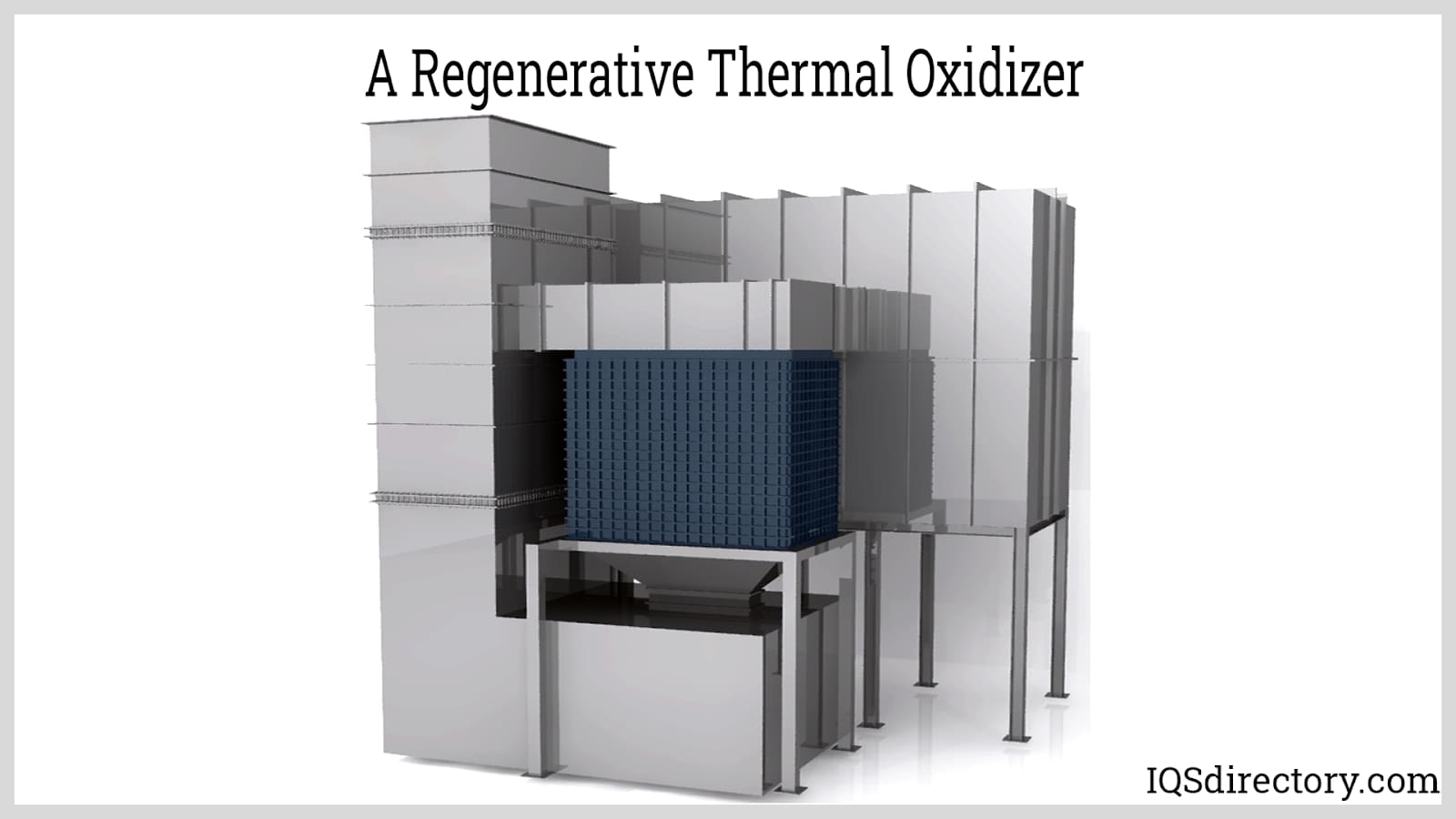

Regenerative Thermal Oxidizers

RTOs are modern air pollution prevention incinerators built to recover heat from oxidation. In this kind of oxidizer, a ceramic bed is utilized to warm up the gas stream before entering the combustion chamber, which serves as the fuel source to oxidize the gases. This process prevents the stream from being instantly subjected to the combustion temperature. As a result, it operates at far lower temperatures than direct-fired oxidizers, between 1,400 to 1,510 °F.

Oxidizer Applications

Industrial emission is the main cause of air pollution. Numerous pollution control equipment, including oxidizing agents, air and wet scrubbers, precipitators, vacuum cleaners, fog collectors, and wet scrubbers, are available to control the release of toxic gases of various sorts into the atmosphere. Depending on the application, each device is made to regulate the emission of various toxic gases and particles from stationary sources' exhaust air streams. However, most of them still need to develop sufficiently to offer any value to production. However, some have, such as the regenerative oxidizer, frequently used to recycle heat from the facility's exhaust processing to power other processes.

Choosing the Correct Oxidizers Supplier

To make sure you have the most beneficial outcome when purchasing Oxidizers from an Oxidizers Manufacturer, it is important to compare at least 5 or 6 Companies using our list of Oxidizers suppliers. Each Oxidizers Manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Oxidizers company website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Oxidizers businesses with the same quote.

Air Compressors

Air Compressors  Air Filters

Air Filters Air Pollution Control

Air Pollution Control Blowers

Blowers Dust Collectors

Dust Collectors Industrial Vacuum Cleaning Equipment

Industrial Vacuum Cleaning Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services