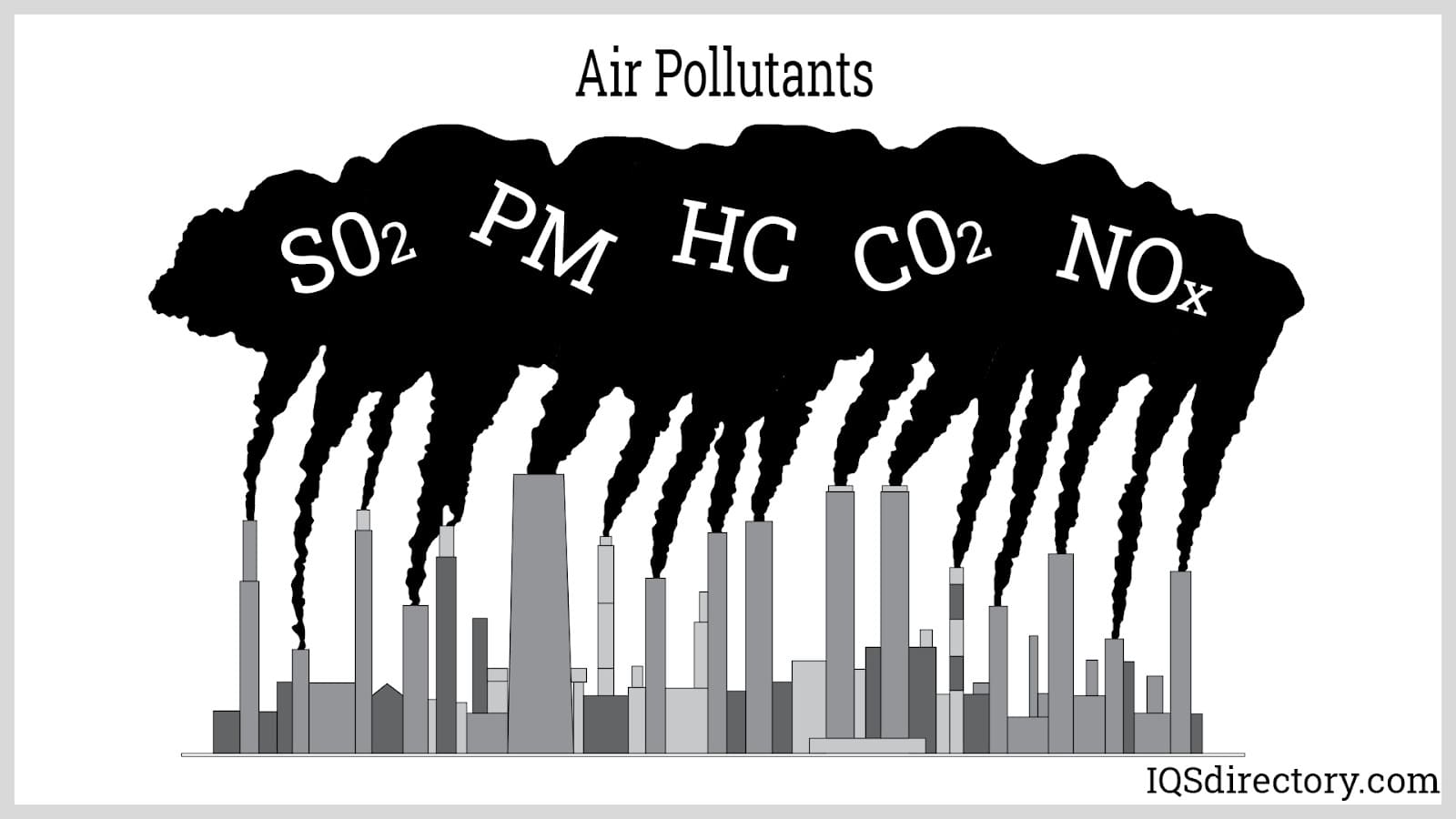

Pollution control techniques are necessary in today’s world. Air pollutants are produced by both human-made causes and natural causes such as volcanic eruptions and wildfires. Moving sources, such as aircraft, trains, and vehicles, are called mobile sources, in contrast with stationary sources such as power plants, industries, and other facilities. Read More…

Anguil Environmental provides highly-engineered, environmental equipment and service solutions that help clients solve complex industrial air pollution control and wastewater treatment challenges across the globe. Anguil air pollution control systems include thermal and catalytic oxidation technologies for compliance with VOC, HAP and odor regulations.

Dürr is a leading global supplier of environmental solutions and engineered products tailored to meet customers' industrial process requirements. We offer a complete portfolio of air pollution control technologies including scrubbers, wet electrostatic precipitators, thermal and catalytic oxidizers, and solvent recovery systems.

The CMM Group provides design and build, and technical engineering services for VOC emission control, odor abatement solutions and energy recovery systems. CMM Aftermarket Services team provides preventive maintenance and inspection services, controls upgrades, retrofit and rebuild services to extend the life of existing equipment. For small or large, complex projects, The CMM Group’s extensive ...

Pollution Systems designs, manufactures and installs highly reliable industrial air pollution control equipment. We offer Thermal Oxidizers, Catalytic Oxidizers, Regenerative Thermal Oxidizers, Direct Fired Oxidizers, Enclosed Flares, Gas Scrubbers, Particulate Scrubbers, Rotor Concentrators and Heat Recovery Systems. On-site services through our dedicated service company include equipment...

Meet stringent environmental regulations with Ducon's complete line of the most advanced air pollution control equipment: cyclones, scrubbers, incinerators, electrostatic precipitators, activated carbon absorbers, gas absorption towers, flue gas desulfurization, chemical strippers, NOx & VOC Control, etc.

More Emission Control System Manufacturers

In high enough quantities, pollutants created by mobile or stationary sources can have negative consequences for the atmosphere, the environment, and human existence, such as rising global average temperatures, reducing atmospheric visibility, lowering air quality, and impacting human health. For this, the Environmental Protection Agency (EPA) enacted the Clean Air Act (CAA), which put rules on both sources of air pollution to reduce their impact on the atmosphere, the environment, and human life. Examples of standard auxiliary components and equipment used in emission control systems include:

- Pollution control and monitoring systems

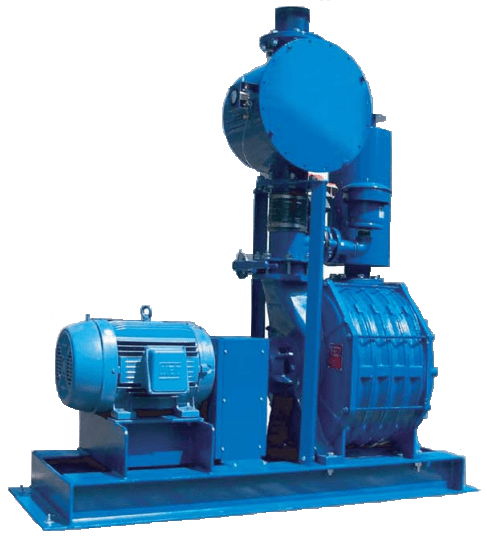

- Blowers and fans

- Blade dampers

- Stacks

- Heat exchangers

Types of Emission Control Systems

Some examples of air pollution control devices used in industrial settings are:

Scrubbers

Scrubbing is a physical procedure that removes particles and gasses from industrial pollutants before they are discharged into the environment. industrial scrubbers are divided into two categories: dry and wet scrubbers.

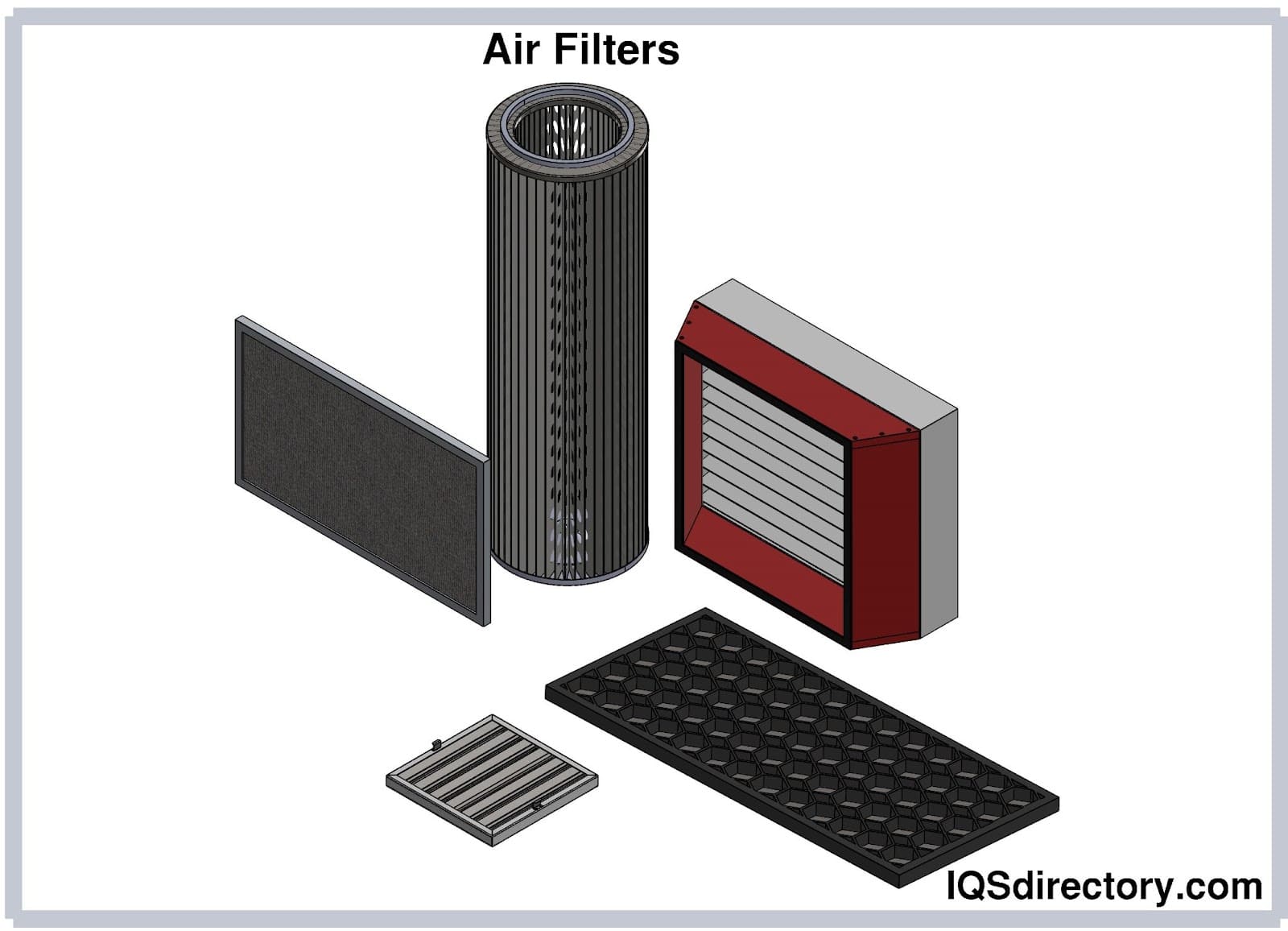

Air Filters

Air filters are pollution-control devices that use a specific type of filtering medium, such as cloth, sintered metal, or ceramic, to collect and remove dry particles and pollutants from air flowing through them, such as dust, chemicals, microorganisms, and so on.

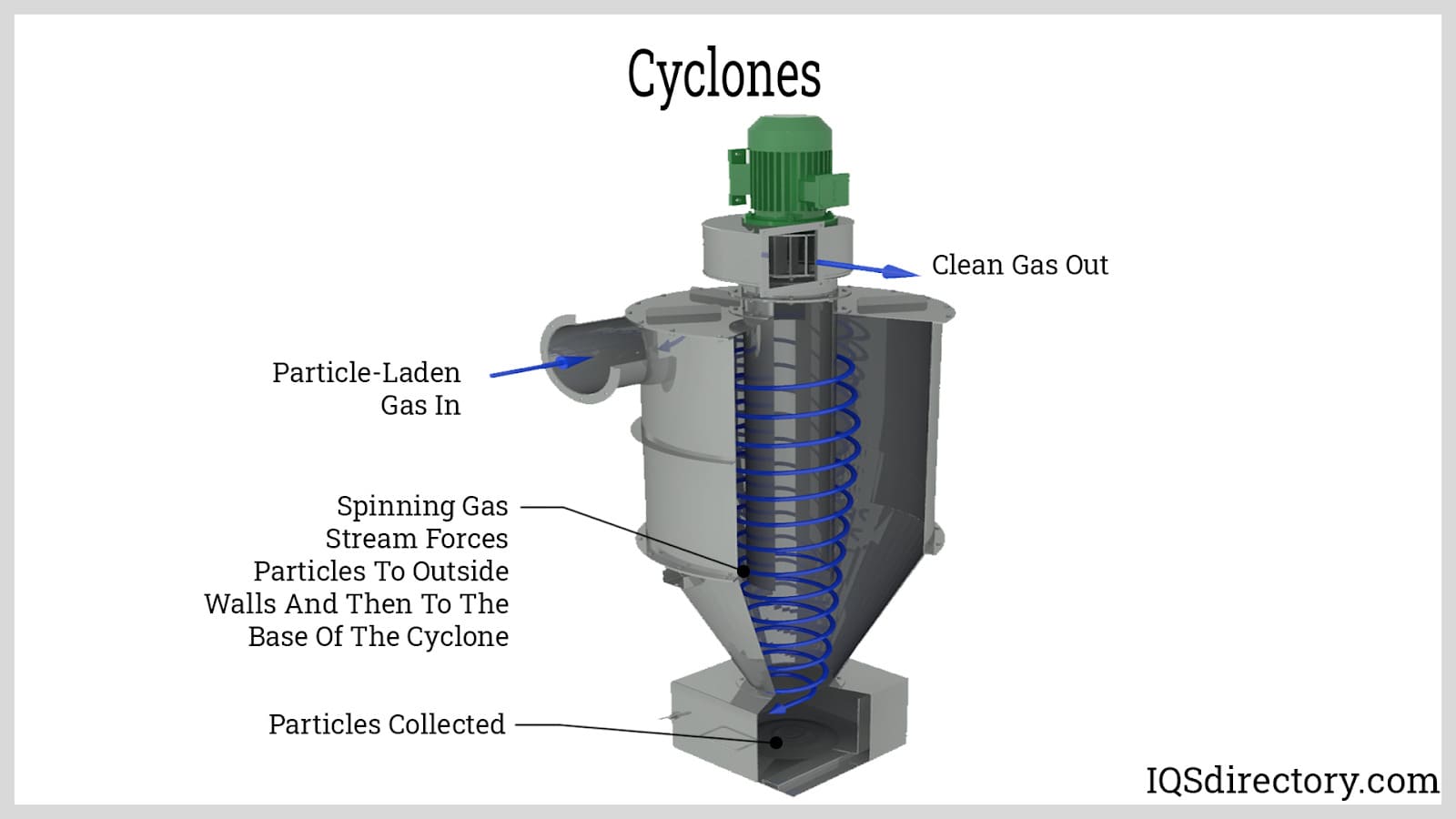

Cyclones

Dry particulate matter is separated from gaseous emissions by cyclone dust collectors. They catch and remove particles using centrifugal force. When a gas stream enters a cyclone, they spiral around the cylindrical chamber.

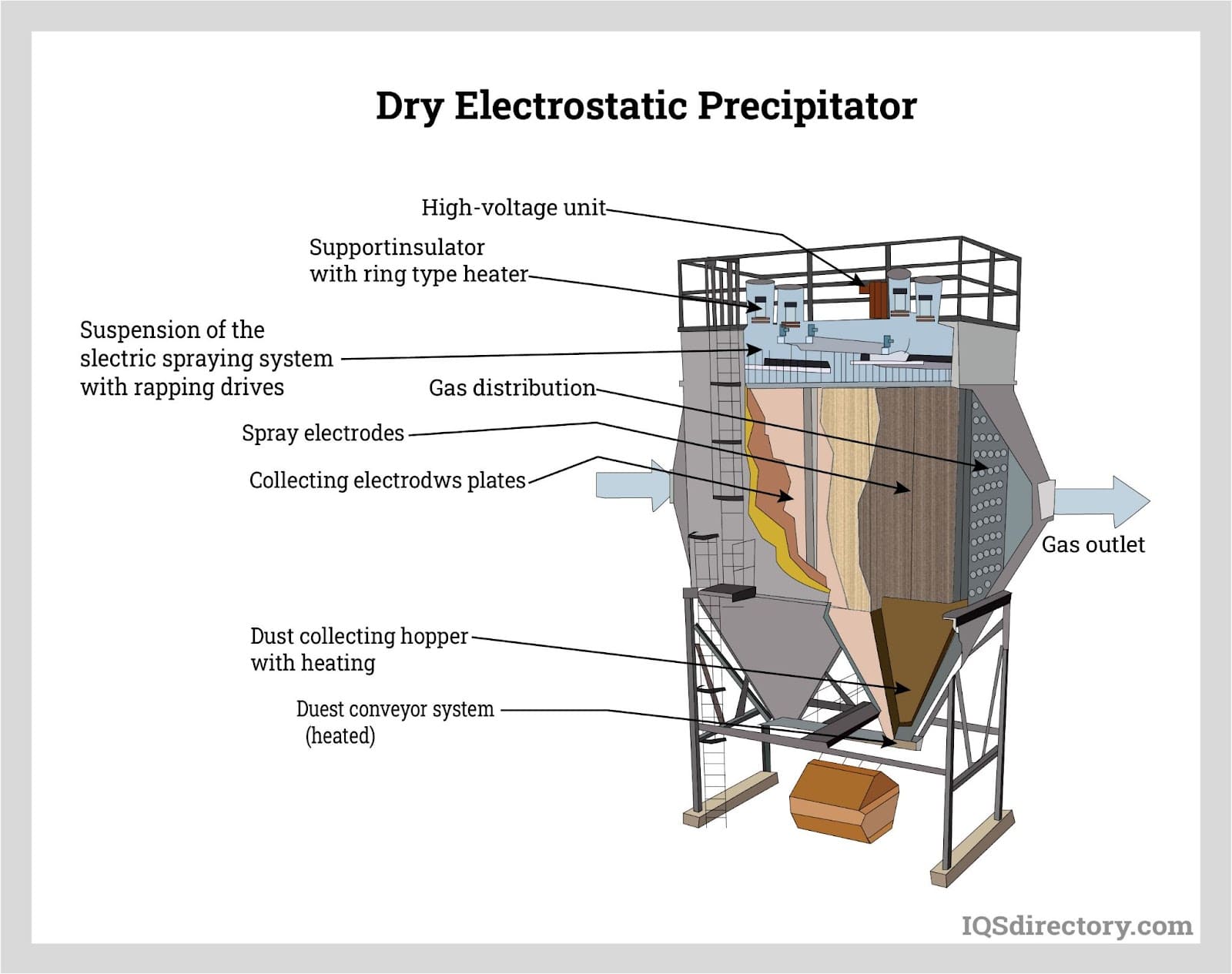

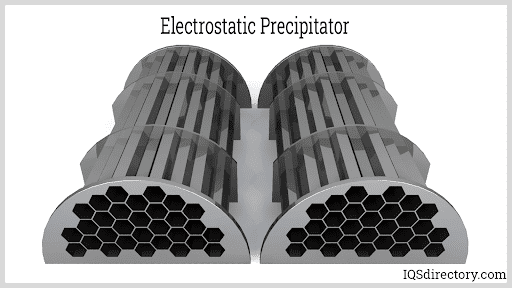

Electrostatic Precipitators (ESPs)

ESPs use transformers to generate a significant static electrical potential difference between the charging electrodes and the collecting plates. When gas streams pass between the two components, an electrical charge is introduced to the particles, attracting the particulate matter to the collecting plates.

Mist Collectors

These devices utilize thin mesh-like filters to separate liquid droplets from gas and collect them in a separate chamber for processing and, in some cases, recovery and reuse.

Incinerators

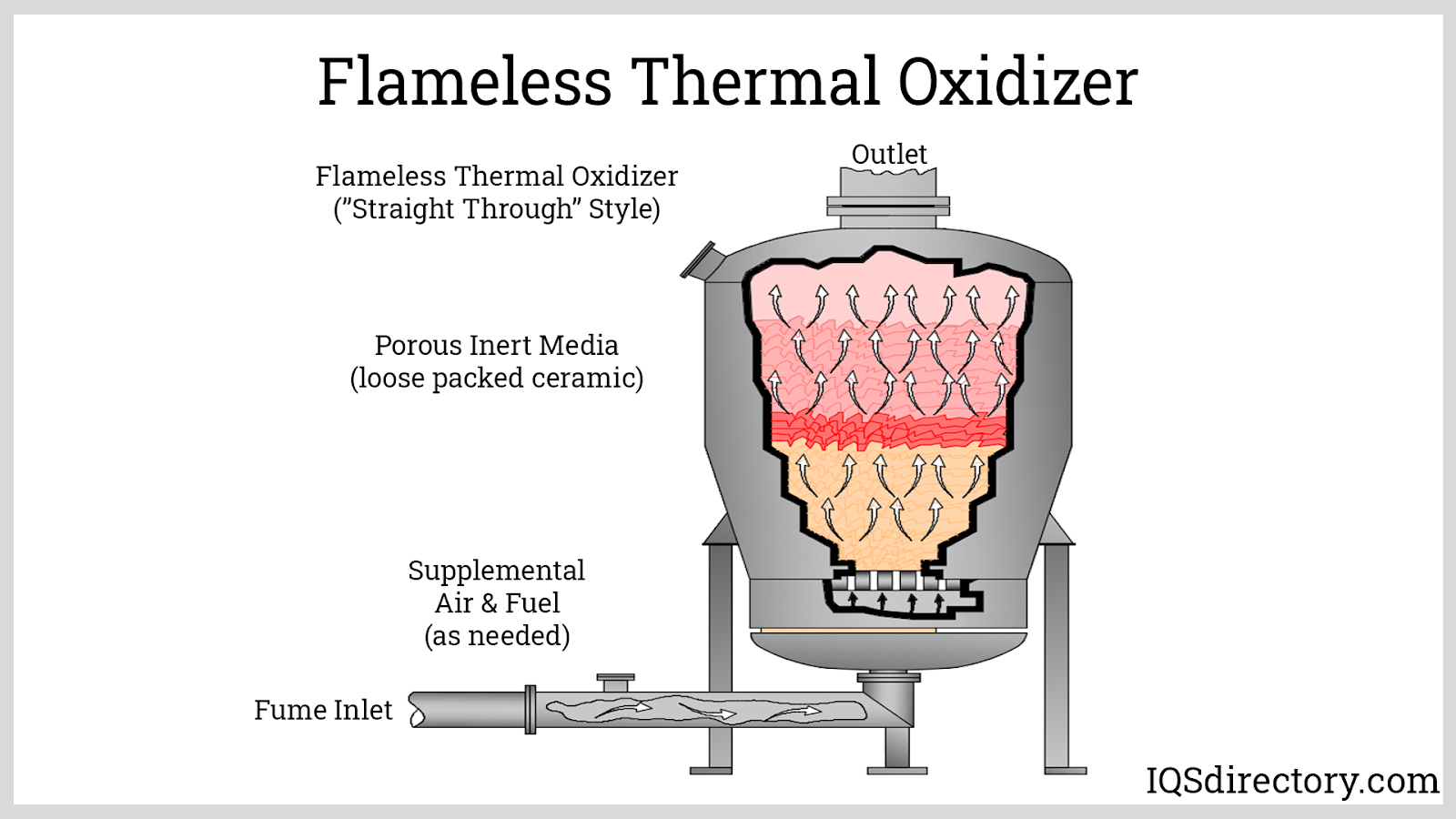

Incinerators use combustion technologies to convert pollutants into non-toxic byproducts. They are frequently used in various industrial applications to control gas emissions and preserve air quality.

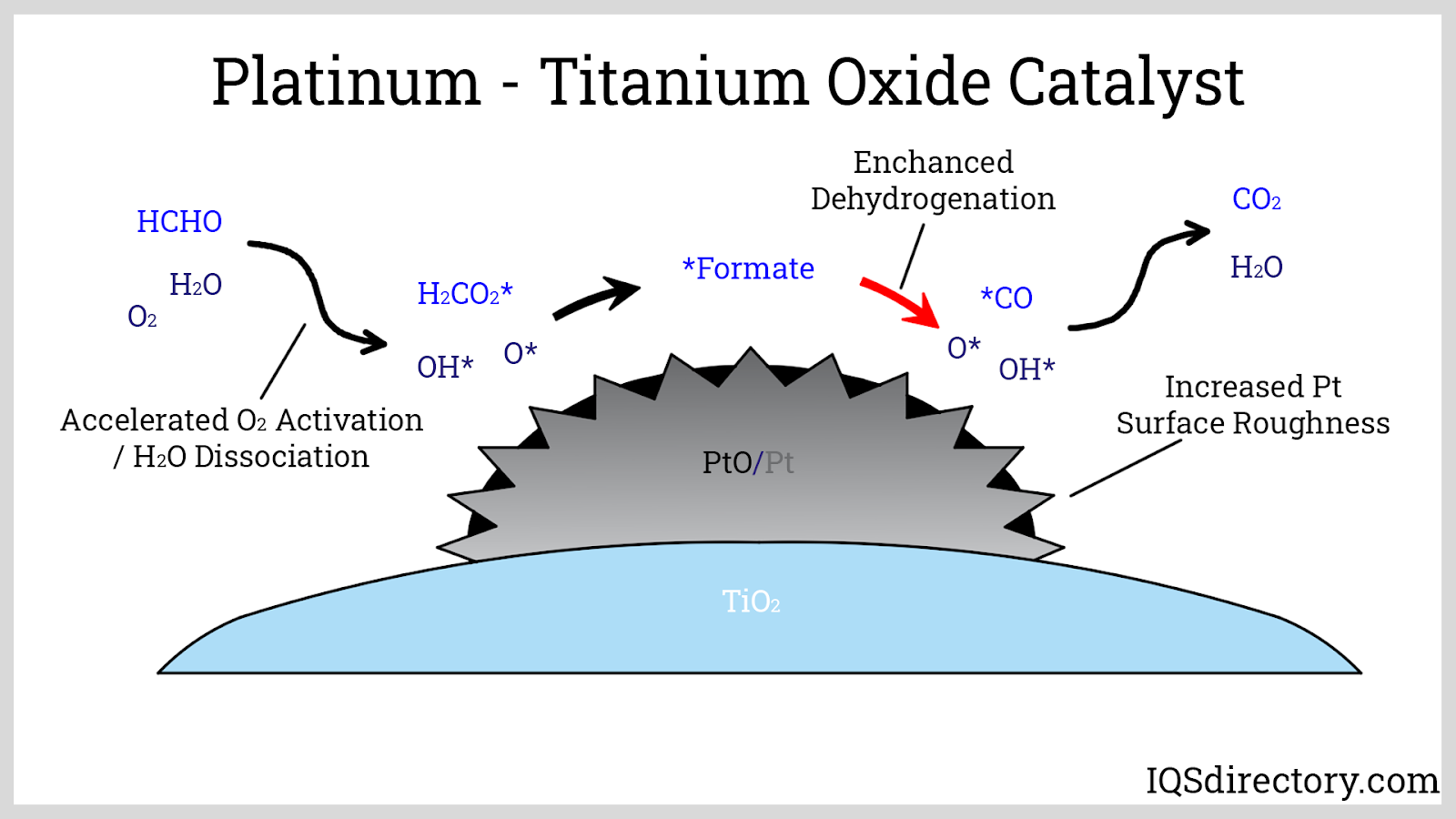

Catalytic Reactors

Catalytic reactors, also known as selective catalytic reduction (SCR) systems, are air pollution control devices commonly employed to reduce nitrogen oxide emissions caused by the combustion of fossil fuels in industrial applications.

Biofilters

Microorganisms such as bacteria and fungus break down and eliminate water-soluble substances in biofilters. Biofilters minimize the number of contaminants in industrial emissions and exhaust by destroying them.

Construction of Emission Control Systems

- As with many other air filtration systems, wet scrubbers and air scrubbers use pools or streams to attract and remove particles from the air.

- Though not always complicated, industrial emission control requires installing massive equipment.

- Systems might be as little as a catalytic converter in a car or as large as a smokestack scrubber.

Working of Emission Control System

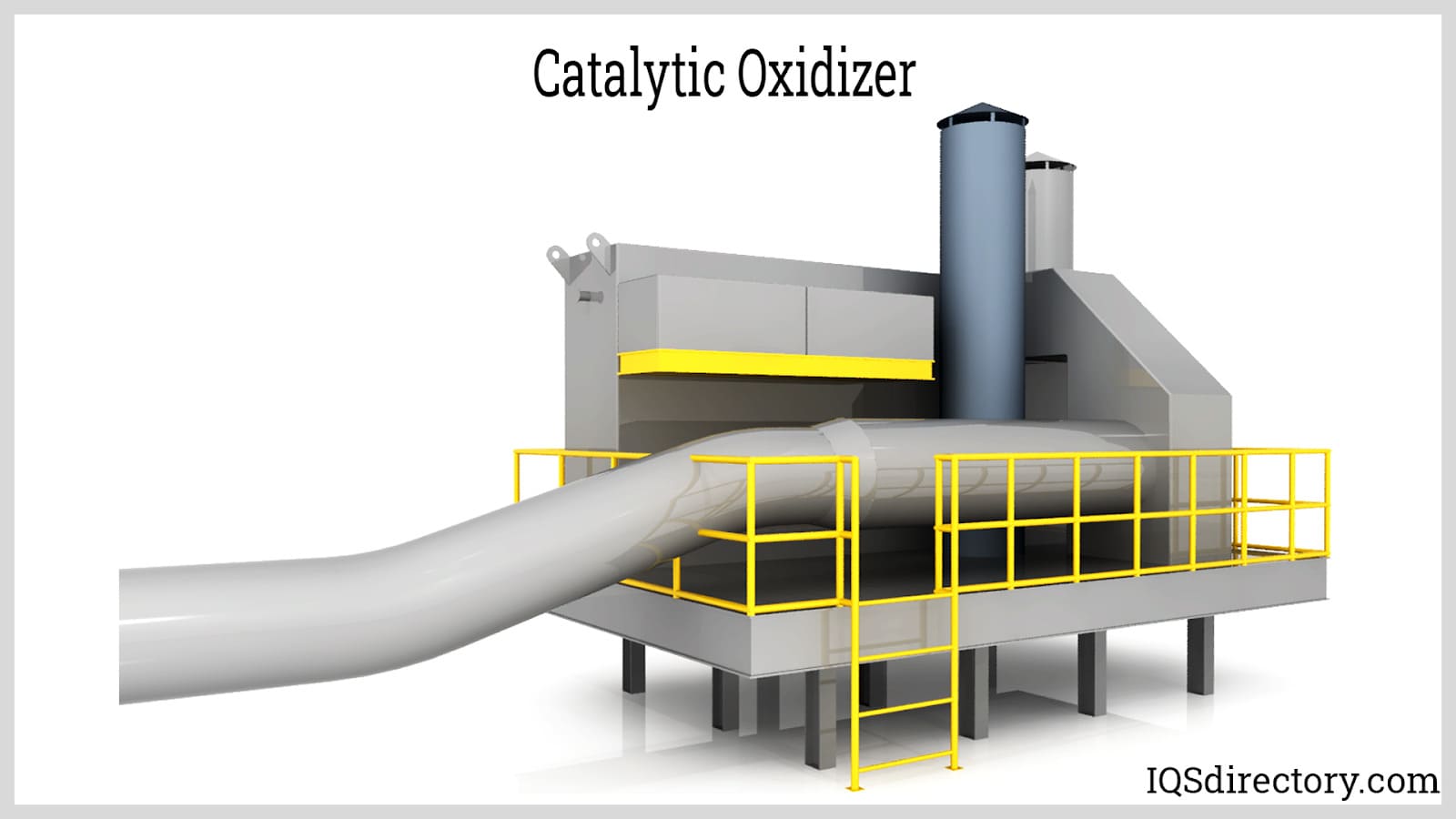

- Before passing through the catalyst, air enters the oxidizer chamber and is heated.

- The air is heated to the temperature required for catalyst activation, which varies.

- When unclean air is exposed to the catalyst in the presence of excess oxygen at the required temperature, the VOCs are converted to carbon dioxide, water vapor, and thermal energy.

- Catalytic and thermal oxidizers are employed to break down contaminants and clean the air by heating materials to severe temperatures.

- Heat recovery systems are commonly used in systems that utilize incendiary temperatures to offset the expense of operations.

Benefits of an Emission Control System

- Contaminants collected by mist collectors and other similar devices can be recycled.

- As a result, the air pollution management sector benefits the environment, worker safety, and business.

- Typical destruction effectiveness is more than 95%.

- An electric catalytic oxidizer, which utilizes electricity rather than gas, is more environmentally friendly.

- Computer-controlled fuel-injection systems guarantee more exact air-fuel mixes, resulting in increased combustion efficiency and decreased pollution output.

Applications of Emission Control Systems

- Emission control systems can transform these pollutants into water vapor and carbon dioxide, which may then be safely discharged or recirculated into the environment.

- These systems are used in the automotive, pharmaceutical, medical, microelectronic, bio-safe laboratories, and aerospace sectors, to name a few.

- These control systems are found in power plants and metallurgical facilities.

- A pollution control system is used in oil and gas refineries.

- Air pollution control systems are used in chemical manufacturing because of the gases and contaminants in the environment.

- Many facilities use continuous emissions monitoring systems to help manage and monitor dangerous discharges, making reporting to federal and state supervisory bodies easier.

Choosing the Right Emission Control System Supplier

To make sure you have the most productive outcome when purchasing Emission Control Systems from an Emission Control System Supplier, it is important to compare at least 5 or 6 Companies using our Emission Control Systems directory. Each Emission Control System Supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Emission Control System business website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Emission Control System businesses with the same form.

Air Compressors

Air Compressors  Air Filters

Air Filters Air Pollution Control

Air Pollution Control Blowers

Blowers Dust Collectors

Dust Collectors Industrial Vacuum Cleaning Equipment

Industrial Vacuum Cleaning Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services