Industrial vacuum cleaners are used exclusively by professionals for building maintenance and industrial workspace cleaning. Commercial vacuum cleaners may be used for similar purposes, but they are characterized less by efficiency and use in heavy duty cleaning processes as much as they are by economy and use in light duty cleaning processes. Read More…

Anguil Environmental provides highly-engineered, environmental equipment and service solutions that help clients solve complex industrial air pollution control and wastewater treatment challenges across the globe. Anguil air pollution control systems include thermal and catalytic oxidation technologies for compliance with VOC, HAP and odor regulations.

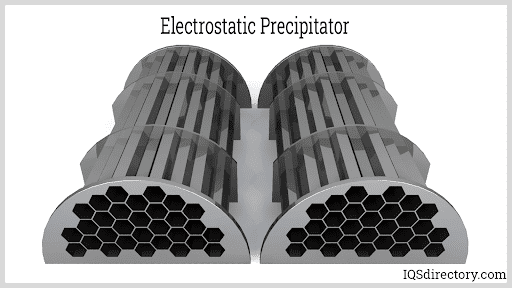

Dürr is a leading global supplier of environmental solutions and engineered products tailored to meet customers' industrial process requirements. We offer a complete portfolio of air pollution control technologies including scrubbers, wet electrostatic precipitators, thermal and catalytic oxidizers, and solvent recovery systems.

The CMM Group provides design and build, and technical engineering services for VOC emission control, odor abatement solutions and energy recovery systems. CMM Aftermarket Services team provides preventive maintenance and inspection services, controls upgrades, retrofit and rebuild services to extend the life of existing equipment. For small or large, complex projects, The CMM Group’s extensive ...

Pollution Systems designs, manufactures and installs highly reliable industrial air pollution control equipment. We offer Thermal Oxidizers, Catalytic Oxidizers, Regenerative Thermal Oxidizers, Direct Fired Oxidizers, Enclosed Flares, Gas Scrubbers, Particulate Scrubbers, Rotor Concentrators and Heat Recovery Systems. On-site services through our dedicated service company include equipment...

Meet stringent environmental regulations with Ducon's complete line of the most advanced air pollution control equipment: cyclones, scrubbers, incinerators, electrostatic precipitators, activated carbon absorbers, gas absorption towers, flue gas desulfurization, chemical strippers, NOx & VOC Control, etc.

More Vacuum Cleaner Manufacturers

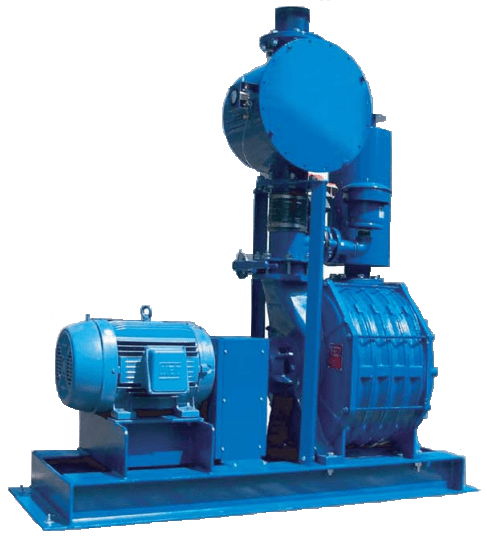

Vacuum varieties are vast and include small vacuum cleaners and portable vacuum cleaners, which can be designed for industrial use, but they are mainly used in commercial contexts in less demanding applications. In industrial settings like woodworking, metalworking, or other processes that create a constant flow of debris, vacuum equipment that operates on a higher level than commercial vacuums is needed. Continuous duty vacuums are built to operate 24 hours a day with limited interruption; in settings where dangerous debris is created regularly, explosion proof vacuums may be necessary to reduce the risk of fire or other danger. Sometimes HEPA vacuum cleaners are put to use on manufacturing floors to help filter workspace air while vacuuming. Auto vacuums, some of which can be wet/dry vacuums, are high-capacity, specialized vacuums used in the cleaning of vehicles. In building maintenance applications and in some industrial settings, central vacuum systems allow for the collection of debris throughout a building by central vacuums that connect to built-in vacuuming duct work. Every manufactured product available has to be made somewhere, and most of them come from companies that use a streamlined process to maximize output. These processes produce excess bits of stuff in huge quantities, and something has to clean up after them.

Vacuum cleaners can be the perfect industrial cleaning tools; unlike sweepers, they don't kick up dust, which in some cases can be hazardous, and their use is minimally labor intensive. Vacuums can be configured to pick up almost anything; fine powders, abrasives, explosive media, litter, non-free flowing media, metalworking chips, toxic media, coolant, oil mist and welding fumes are all fair game, though a vacuum designed for picking up wood chips differs in design from one that vacuums fluid waste. Some of the waste materials produced by industrial processes can be reclaimed and reused after processing. Vacuums are an excellent means of collecting waste industrial materials for reuse. They don't damage the material, and specialized filters can be designed to minimize the number of unwanted materials like dust or dirt collected by accident. After being collected, the waste materials can be cleaned if necessary and then reprocessed for future use. An added benefit of using vacuums to clean workspaces is that they can be fitted with HEPA filters; in environments where a high volume of waste shavings or dust are created, HEPA filter vacuums can remove the large particles as well as fine particulates that degrade workspace air quality. A vacuum is an area from which air has been fully or partially removed. On the earth's surface, every object is subject to the force exerted by the weight of air. When air pressure in one area decreases, more highly pressurized air from nearby floods into the lower-pressure area until equilibrium is achieved; this is what causes wind. Vacuum cleaners use a fan or system of fans to artificially lower air pressure in the enclosures where they collect debris. The more highly pressurized air outside of the enclosure rushes in, bringing nearby dust, dirt, debris or fluid with it, depending on how strong the vacuum cleaner is. Every vacuum configuration is different. Small, portable vacuum cleaners can collect debris in fabric filter bags or removable plastic containers. Sometimes disposable filters are lined with larger, removable filters to provide extra air filtering. Almost every variety of vacuum cleaner is designed to connect with attachments that allow for vacuuming in different places. Vacuums for carpet cleaning usually feature an agitator for easier removal of dirt from carpet fibers, and auto vacuums use special attachments that help them clean tight spaces more easily. Continuous duty vacuums feature large collection enclosures that can be emptied quickly and easily so the machine can be put back to work without too much delay. Backpack vacuum cleaners, canister vacuums, rider or walk-behind vacuum cleaners, and vacuum cleaner trucks are just a few of the available portable vacuum cleaner configurations. The overwhelming majority of vacuum cleaners are at least semi-portable, and most of them are very portable. Even continuous duty vacuums, which can be quite large and are generally used only for the constant cleaning of warehouse or factory workspaces, are often equipped with wheels. Central vacuum systems are the least portable of all vacuum cleaner systems. In large-scale building maintenance contexts where constant cleaning is required, central vacuum systems are a good solution to the problem of maintaining efficiency. Through inlets in a built-in system of ductwork, maintenance employees can connect hoses and vacuum attachments to a single central vacuum located in a mechanical closet. Because the central vacuum is isolated, and its room is usually located in a basement, the noise generated by vacuuming is very limited compared to most portable vacuums. This feature is invaluable in contexts like colleges where vacuuming is needed even as classes are proceeding. Instead of using many vacuums with many filters, maintenance crews that use central vacuums have only one machine to empty and service.

Vacuum Cleaner - Adwest Technologies, Inc.

Vacuum Cleaner - Adwest Technologies, Inc.

Air Compressors

Air Compressors  Air Filters

Air Filters Air Pollution Control

Air Pollution Control Blowers

Blowers Dust Collectors

Dust Collectors Industrial Vacuum Cleaning Equipment

Industrial Vacuum Cleaning Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services