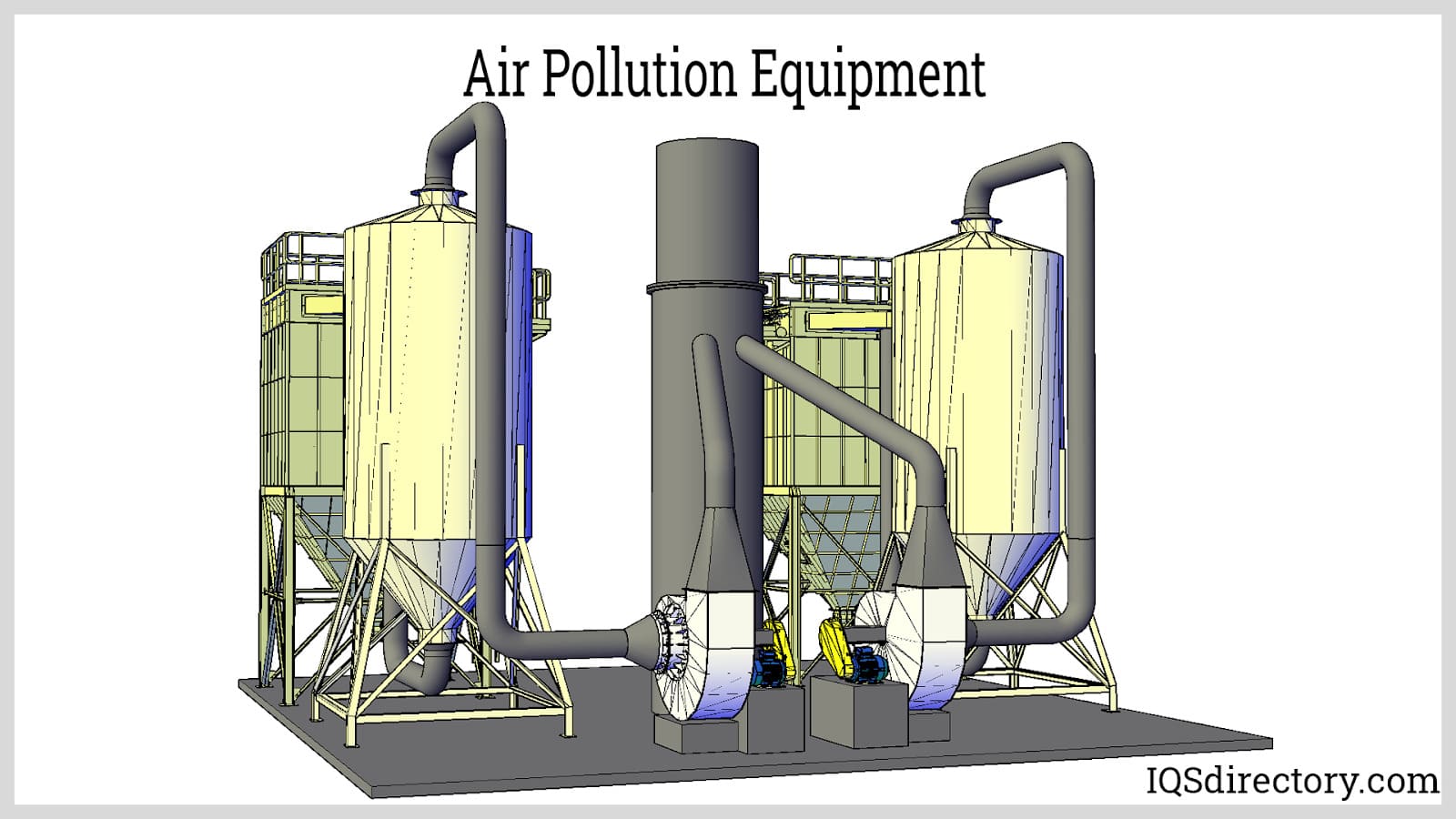

Air pollution control equipment eliminates harmful gasses such as sulfuric gasses, fumes, smells, vapors, Volatile Organic Compounds (VOCs), and Hazardous Air Pollutants (HAPs) from the air. The environment, local ecosystems, and human health are all threatened by VOCs and HAPs. Read More…

Anguil Environmental provides highly-engineered, environmental equipment and service solutions that help clients solve complex industrial air pollution control and wastewater treatment challenges across the globe. Anguil air pollution control systems include thermal and catalytic oxidation technologies for compliance with VOC, HAP and odor regulations.

Dürr is a leading global supplier of environmental solutions and engineered products tailored to meet customers' industrial process requirements. We offer a complete portfolio of air pollution control technologies including scrubbers, wet electrostatic precipitators, thermal and catalytic oxidizers, and solvent recovery systems.

The CMM Group provides design and build, and technical engineering services for VOC emission control, odor abatement solutions and energy recovery systems. CMM Aftermarket Services team provides preventive maintenance and inspection services, controls upgrades, retrofit and rebuild services to extend the life of existing equipment. For small or large, complex projects, The CMM Group’s extensive ...

Pollution Systems designs, manufactures and installs highly reliable industrial air pollution control equipment. We offer Thermal Oxidizers, Catalytic Oxidizers, Regenerative Thermal Oxidizers, Direct Fired Oxidizers, Enclosed Flares, Gas Scrubbers, Particulate Scrubbers, Rotor Concentrators and Heat Recovery Systems. On-site services through our dedicated service company include equipment...

Meet stringent environmental regulations with Ducon's complete line of the most advanced air pollution control equipment: cyclones, scrubbers, incinerators, electrostatic precipitators, activated carbon absorbers, gas absorption towers, flue gas desulfurization, chemical strippers, NOx & VOC Control, etc.

More Pollution Control Equipment Manufacturers

Some consequences are acid rain, pollution, carbon emissions, and global climate change. Without pollution control technology, airborne contaminants offer major health concerns ranging from moderate irritation to severe allergic reactions and would be far more prevalent. Several regulatory bodies, such as the EPA, mandate air pollution control devices and monitors to guarantee that levels are kept healthy to battle all sorts of harm caused by excessive emissions.

Manufacturing activities frequently result in the emission of undesirable byproducts such as hydrocarbons, solvent vapors, and halogenated and hazardous air pollutants that should not be discharged into the environment or experienced by the general public.

The Purpose of Pollution Control Equipment

- Pollution control equipment, also known as emission control systems , removes particulates and contaminants through filtration, absorption, extraction, or a combination of these methods.

- Each unit is designed to ensure dependable, energy-efficient performance based on the facility's demands and output.

- At its basic level, industrial air pollution control devices absorb and neutralize pollutants, preventing them from being discharged into the atmosphere and converting them to water vapors or thermal energy.

- The units absorb pollutants such as noxious smells, volatile organic compounds (VOCs), hazardous air pollutants (HAPs), and nitrogen oxides.

- Heat recovery systems can be used to improve efficiency and lower operating costs by recovering a large portion of heat energy generated during heat system usage.

Types of Pollution Control Equipment

Continuous Emissions Monitoring Systems (CEMS)

Many facilities employ CEMS systems to track, regulate, and report emissions. Monitoring equipment consists of numerous instruments used to measure the number of gaseous and particulate matter directly at various places.

Parametric Monitoring

In parametric monitoring, emissions are monitored by keeping track of critical parameters connected to the operation of process equipment. It's proven to be a more adaptable and cost-effective way to certify compliance.

Emission Control Systems

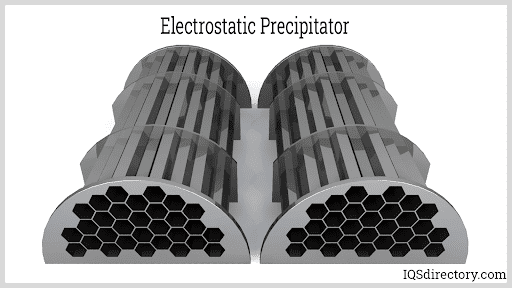

These systems assist in keeping air pollution levels within limits. These air filters may treat an exhaust stream's supply, allowing a factory to stop polluting the environment. Depending on the work, industrial facilities may use mist collectors, electrostatic precipitators, odor control systems, wet scrubbers, dry scrubbers, or other air filters.

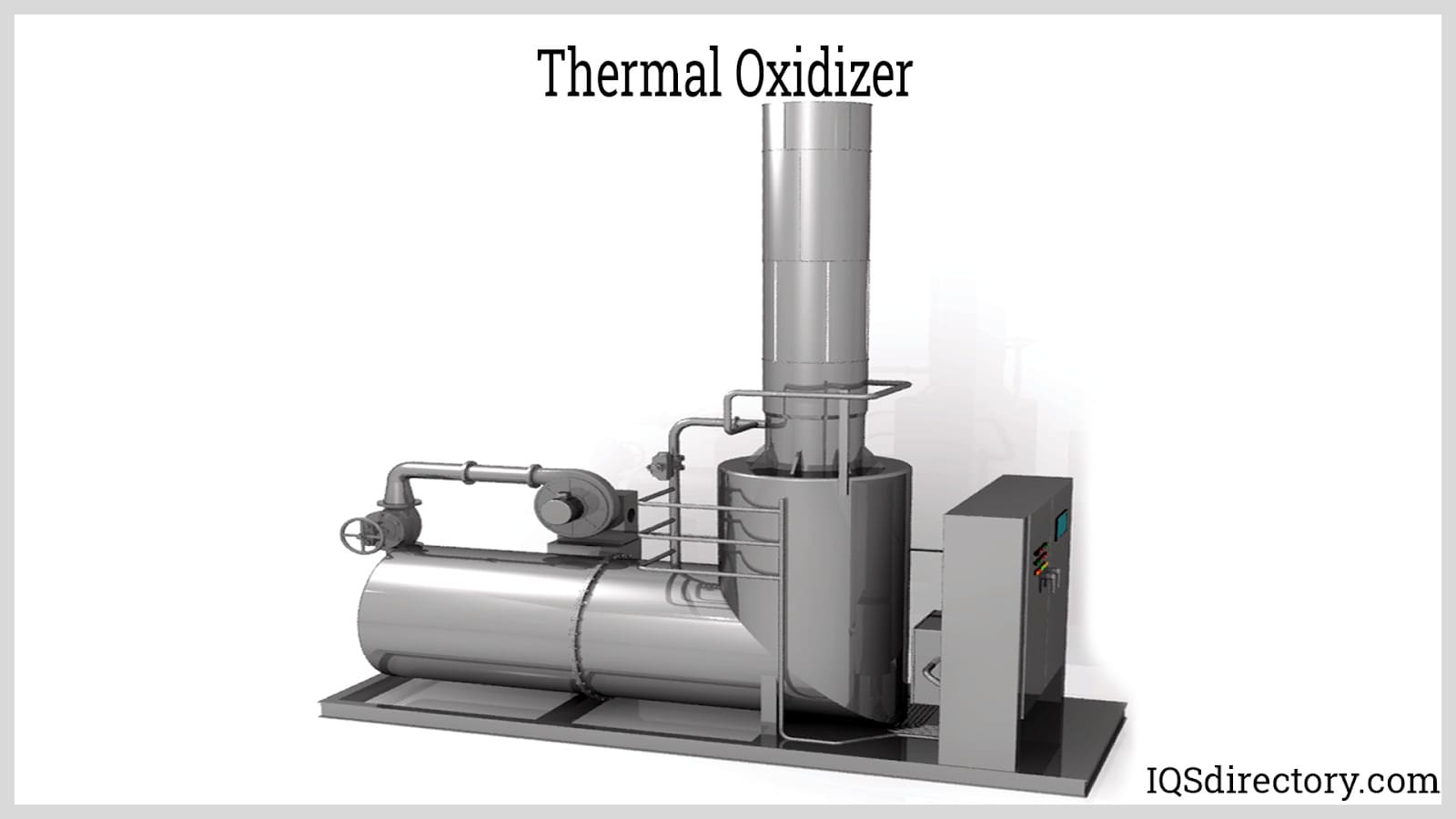

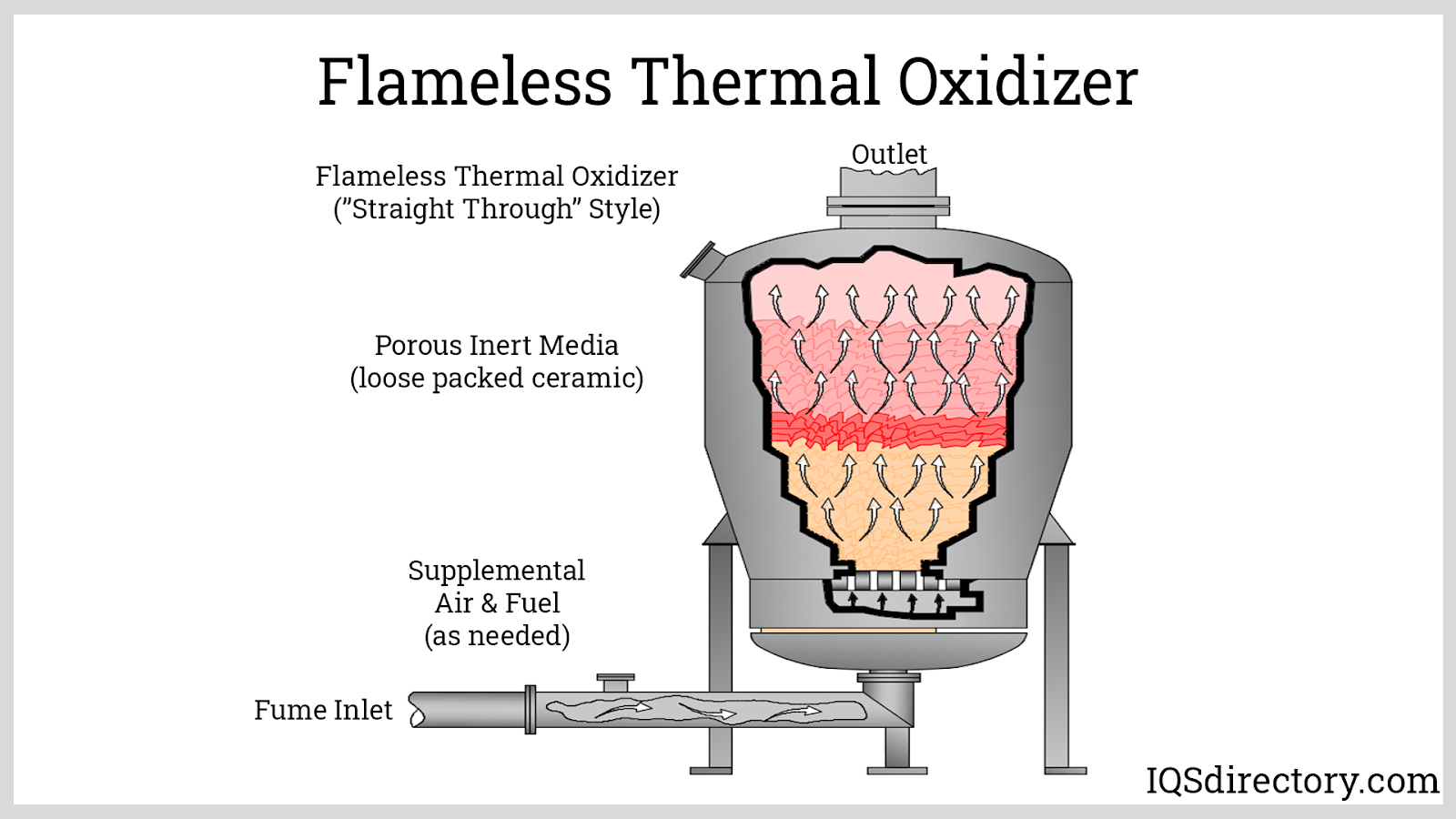

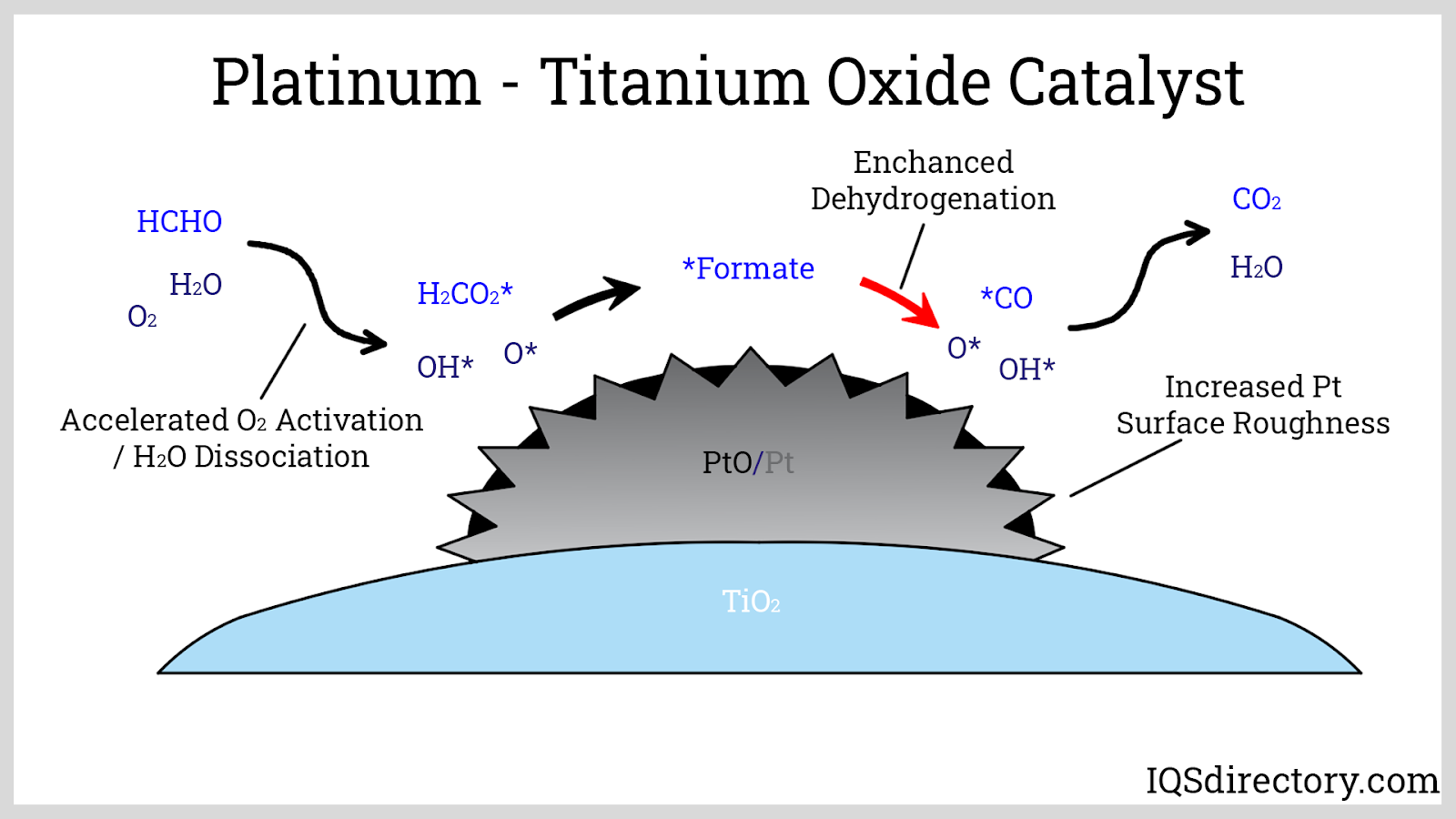

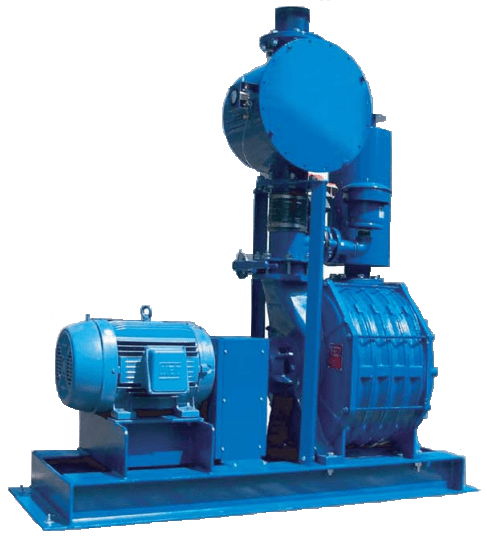

Oxidizer

An oxidizer burns pollutants at the machine's heart to break them up and recreate them into non-toxic carbon. Catalytic oxidizers, thermal oxidizers (including regenerative thermal oxidizers and recuperative oxidizers), and carbon absorbers are all common oxidizers.

Working of Pollution Control Devices

There are three ways that air pollution control devices can work:

Chemical modification

This process entails transforming a hazardous substance into a harmless one. This is commonly accomplished using an electrostatic precipitator for flue gas desulfurization. If VOCs have a high recovery value, experts can recover materials via carbon adsorption, scrubbing, and condensation. If not, experts can use thermal oxidation, catalytic oxidation, or biofiltration to remove the contaminants.

Contaminant Destruction

This is the most challenging type of air purification since it requires high enough boiling temperatures to burn away compounds with extremely high boiling points.

Hazard Removal

The most systematic and straightforward air purification method is removing the hazard from the air. This may be accomplished in various forms, but the most common way is to use air filtration systems.

How to Control Pollution

- Meeting federal, state, and municipal standards regulating emissions from factories to autos and everything in between requires the capacity to remove pollutants with a high success rate.

- Control the spread of air and water pollution by reducing the discharge of dangerous gasses.

- Natural resources must be safeguarded for future generations.

- The health risks of pollutants inhaled and eaten can be reduced in other ways.

- Air pollution control aids in preventing economic waste resulting from dead crops and contaminated water that are restricted or eliminated due to air pollution management.

- Air pollution control protects the air quality within homes.

Applications of Pollution Control Equipment

Pollution control equipment is used in various situations, including commercial and residential settings, automotive, medical, printing, biological research, and other sectors.

- Pollution control equipment is also required to manage and remove toxins already discharged into the environment.

- Non-industrial air pollution control technology is also utilized in homes and automobiles.

- Filtration technology is used in the home to eliminate impurities such as allergies, mold spores, pet dander, and dust churned up by air conditioners.

- Automating precision filtering systems decrease pollution from engines, exhaust pipes, and air conditioning systems.

Choosing the Proper Pollution Control Equipment Supplier

To make sure you have the most constructive outcome when purchasing Pollution Control Equipment from a Pollution Control Equipment Manufacturer, it is important to compare at least 5 or 6 Suppliers using our list of Pollution Control Equipment companies. Each Pollution Control Equipment Manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Pollution Control Equipment company website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Pollution Control Equipment companies with the same message.

Air Compressors

Air Compressors  Air Filters

Air Filters Air Pollution Control

Air Pollution Control Blowers

Blowers Dust Collectors

Dust Collectors Industrial Vacuum Cleaning Equipment

Industrial Vacuum Cleaning Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services